Understanding Plastic Blow Molding Machines: Benefits and Applications

In today's industrial landscape, the widespread use of plastic products underscores the need for efficient manufacturing methods. From packaging to automotive and medical components, many processes depend on plastic blow molding machines to produce lightweight, durable, and cost-effective hollow items. This guide explores how these machines operate, their main categories, key advantages, and their role in modern industrial workflows.

What is a Plastic Blow Molding Machine?

A plastic blow molding machine is essential equipment used to create lightweight, durable, hollow plastic products. Industries rely on these machines for scalable, flexible, and cost-effective packaging solutions.

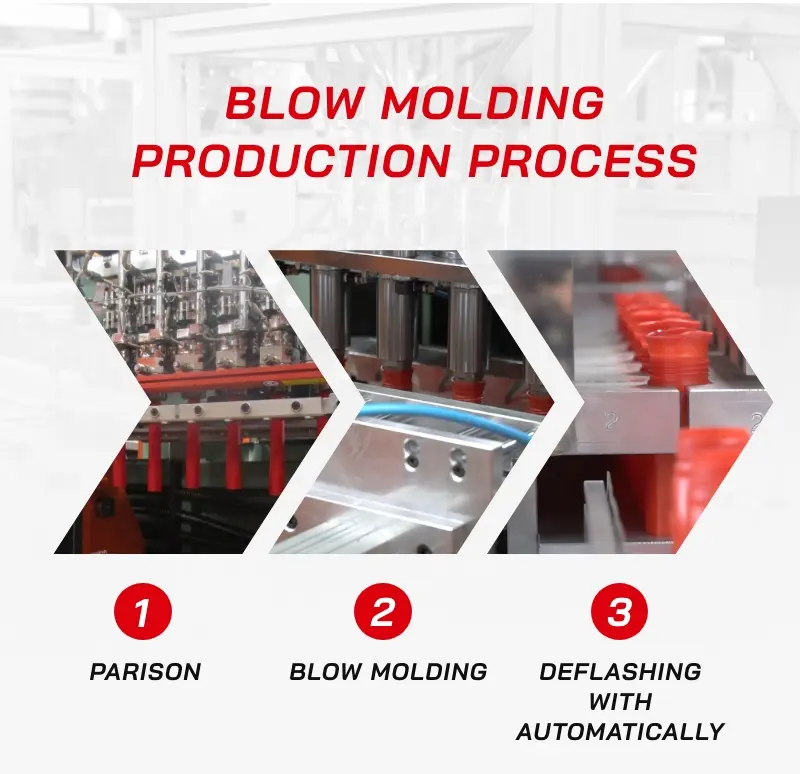

The process starts with heating plastic pellets until they melt. The molten plastic is then extruded into a hollow tube called a parison. This soft plastic tube is carefully controlled to keep its thickness and shape consistent.

Next, a blade trims off excess plastic, and a quick burst of air keeps the tube from sticking together. A blow pin is inserted, and once the mold closes, compressed air inflates the parison into its final shape. After cooling and hardening, the mold opens to release the finished product.

Structure of Plastic Blow Molding Machines

Plastic blow molding machines are vital for modern manufacturing, as they directly influence production speed, cost efficiency, and the final quality of hollow plastic products. To ensure consistent production, plastic blow molding machines depend on a coordinated system of core components. These include the extrusion unit, hopper, heating unit, blow mold, blow unit, cooling system, and transmission system, each playing a key role in the molding process. Let’s take a closer look at five of the core parts:

- Melting unit: This section usually features a barrel and screw system responsible for heating and melting the plastic material until it reaches a workable consistency.

- Blow mold: The mold determines the shape and structure of the finished plastic item, ensuring it matches the intended design.

- Blow unit: Delivers the compressed air required to shape the parison within the mold cavity.

- Cooling system: After forming, this unit helps the plastic solidify quickly and evenly, which is crucial for dimensional stability.

- Transmission system: Manages synchronized mechanical movements across all stages, from feeding to product ejection.

Types of Plastic Blow Molding Machines

Plastic blow molding machines come in various types, each suited for particular materials and production goals. These different techniques result in hollow plastic products that serve a broad spectrum of industrial uses.

Extrusion Blow Molding Machine

Extrusion blow molding is one of the most widely used types of blow molding machines. It works by continuously extruding a parison, which is then cut and clamped into a mold. Compressed air inflates the parison, shaping it to match the mold cavity. Known for its versatility, this method is commonly used to produce bottles, containers, and larger industrial parts with varied shapes and sizes.

Injection Blow Molding Machine

Injection blow molding begins with molding a preform, which is then placed into a blow mold and expanded with compressed air. This results in uniform dimensions and smooth finishes. It's commonly applied to produce medical bottles, cosmetic containers, and pharmaceutical packaging where accuracy and uniformity are essential.

Injection Stretch Blow Molding Machine

In injection stretch blow molding, the preform is first molded, then reheated and stretched before being blown into shape. Stretching enhances both transparency and structural integrity. The process is often chosen for transparent PET packaging such as water bottles, cooking oil containers, and personal care products.

Benefits of Plastic Blow Molding Machines

While each type has its own strengths, all plastic blow molding machines share several key benefits that contribute to their wide use across industries.

1. High Efficiency and Productivity

Automated processes help speed up production, reduce the chance of errors, and keep output consistent. This stability minimizes downtime, even in high-demand environments.

2. Product Diversity and Design Flexibility

With precise temperature control and adaptable molds, blow molding machines are capable of processing a wide variety of resins including PET, HDPE, PP, LDPE, TPU, and PC. This broad material compatibility allows manufacturers to create intricate shapes, multilayered structures, and custom designs that meet the diverse requirements of modern industries.

3. Cost-Effectiveness

Compared to methods that involve costly glass or metal molds, blow molding offers a more budget-friendly alternative. This approach also enables manufacturers to produce thinner-walled products that minimize material usage while retaining strength, making it ideal for high-volume production.

4. Industry Versatility

Blow molding machines are used across a wide range of applications, from food packaging to industrial containers. For products that need long-term storage or chemical resistance, multilayer extrusion can apply recycled plastic for the inner layer and virgin resin with color or protective features for the outer layer. The layered design reduces material usage while improving both strength and overall quality.

5. High Product Strength

Made with high molecular weight plastics, these items are impact-resistant and remain stable under environmental stressors. Such resilience ensures the product remains intact during handling and transport.

6. Suitable for Specialized Products

These containers are especially suited for storing and transporting detergents, chemical reagents, and other reactive substances. With strong resistance to corrosion and chemical degradation, they serve as a dependable solution for industries working with harsh or sensitive liquids.

7. Ideal for Mass Production

When it comes to manufacturing large volumes of plastic containers, blow molding offers exceptional cost efficiency. Its relatively low mold and tooling expenses, combined with the ability to produce various shapes and sizes, help companies manage volume efficiently.

Applications of Plastic Blow Molding Machines

Blow molding machines are used across many fields, supporting everyday products and industrial needs alike. Here are some of the most common applications:

- Food packaging: Bottles for beverages, water, milk, as well as yogurt cups and cheese containers.

- Automotive industry: Fuel tanks, air ducts, and interior components are commonly produced through blow molding due to their need for durability and resistance to harsh environmental conditions.

- Medical and pharmaceutical: Sterile containers, medical bottles, and infusion bags are produced to meet strict hygiene and safety standards required in healthcare settings.

- Household products: Items like refillable cleaning containers, spray bottles, and personal care dispensers designed for everyday convenience and durability.

- Large outdoor containers: Used for storage bins, garden tanks, and industrial drums requiring weather resistance and structural strength.

FAQ

Here are answers to common questions businesses often face when evaluating blow molding machines.

Q1: How much power and cost are needed to produce one plastic bottle?

The power consumption and cost per bottle can vary significantly, primarily influenced by two key factors:

Machine design: This includes the efficiency of heating systems, air compressors, electric motors, servo drives, and cooling units, all of which directly affect how much energy the machine uses during production.

Operational factors: Elements such as raw material types, electricity rates, labor and maintenance requirements, mold and equipment depreciation, as well as auxiliary needs like cooling water, lubricants, and facility overhead all influence overall production costs.

Q2: What are the annual machine maintenance costs for components and servicing?

Annual maintenance costs can vary based on production conditions and usage frequency. Dust, heat, and moisture may accelerate wear, while frequent or extended use raises maintenance needs. Routine preventive care helps reduce repair costs and prolong machine lifespan.

Conclusion

Plastic blow molding machines play a key role in modern manufacturing by combining efficiency, cost-effectiveness, and wide-ranging applications. Choosing the right machine depends on factors like output volume, product design, and automation needs.

Full Shine, an ISO 9001-certified manufacturer, delivers CE-compliant blow molding machines built for consistency and performance. We’re committed to providing smart, innovative, and sustainable solutions for today’s manufacturers. Contact us today to learn more!