Continuous Blow Molding Machine (Horizontal Movement)

Our versatile and efficient plastic blow molding machine can produce a wide variety of products, from 5ml to 10L, with single-station or double-station configurations, monolayer or multi-layer, and 1 to 6 cavities. It is compatible with PE, PP, PETG, PVC, ABS, PA, PS, and co-extrusion materials. An optional view stripe line is also available. This machine is a great choice for businesses that need to produce high-quality plastic products with precise dimensions in a cost-effective and efficient manner.

- Fine steel slide bars for swift mold opening and closing with horizontal motion of carriages by linear slide way.

■ Screw drive in the control of direct-mounted gear box and inverter motor as power saving feature.

■ Die head unit with head-lifted device for cutting melted material swiftly and for easy alignment adjustment. - HMI touch screen (10.4”) from Japan, Fuji, incorporating with PLC System for easy maintenance.

■ Blowing unit driven by hydraulic motor for changing mold easily-- innovative design.

■ Blowing unit, capable of equipping pre-lift feature to form small bottle neck. - Equipped with auto cutting device, conveyor, parison wall thickness controller as option.

■ High-efficient plasticizing extrusion screw for processing materials completely.

■ Full shine special-designed brake system for the carriage to provide stable movement and swift positioning.

■ Close-loop system with servo motor and servo circuit for mold carriage movement, as option.

●Apply for single station/ double station

● Production volume: from 20ml-30L

● Mono layer and multi layers are available

● Cavities: 1~12 cavities

● Apply for PE/PP/PETG/PVC/ABS/PA/ PS/ Co-extrusion material

● Option: view stripe line

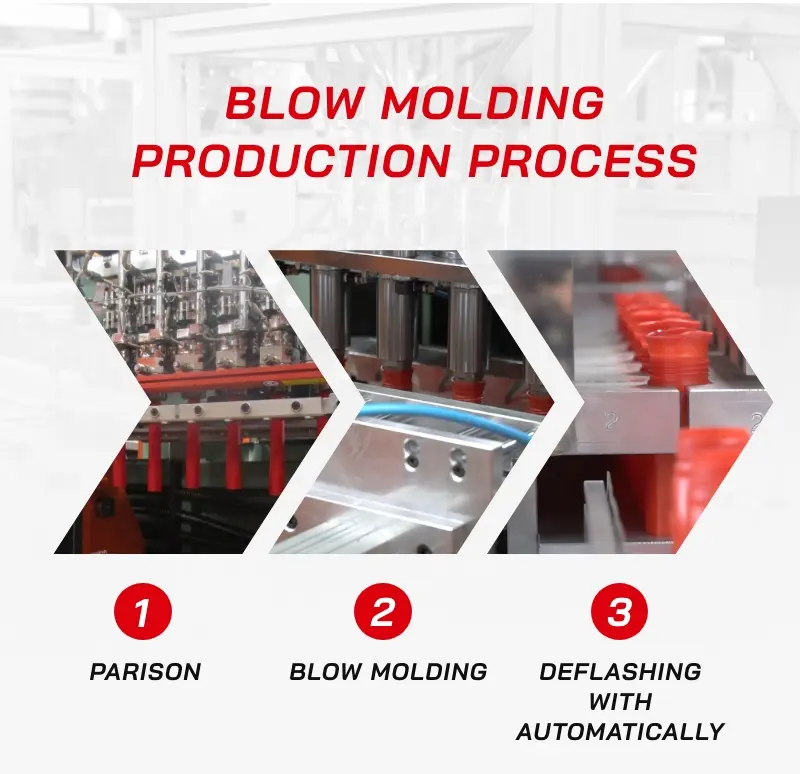

● Support: Hybrid system, Parison control, auto deflashing, turn key solution