Introduction

When it comes to the industrial packaging machine, the blow molding machine is definitely on the list. It’s essential for producing the plastic containers we use every day. FULL SHINE Plastic Machinery aims to provide high-performance blow molding machines. We have extensive experience in producing machines and providing attentive services.

With innovative design and thorough after-sales services, FULL SHINE is the leading blow molding machine manufacturer in this field. All crews, including marketing, R&D, and the service department, have received professional training and education in ISO 9001 management, which is an internationally recognized standard for quality management systems. Thus, our crew members can provide precise services to the customers.

In recent years, FULL SHINE has collaborated with a governmental laboratory to develop advanced technologies. In recognition of our achievement in innovation, we received the Golden Hand Award from the government of Taiwan in December 2006.

Our growth is built on

QUALITY | INNOVATION

PROFESSIONALISM | CONSIDERATION

Philosophy

We use plastic containers and parts every day in various fields, such as food, housing, recreation, and transportation. To improve the quality of these products, FULL SHINE puts effort into delivering superior blow molding machines.

With precise machining devices and user-friendly designs, these machines provide stable, efficient, and productive performance. They can produce containers with capacities from 5ml to 500 liters. These features are favoured by our customers worldwide, from Africa, Asia, Europe, the Middle East, North America, Oceania, and South America.

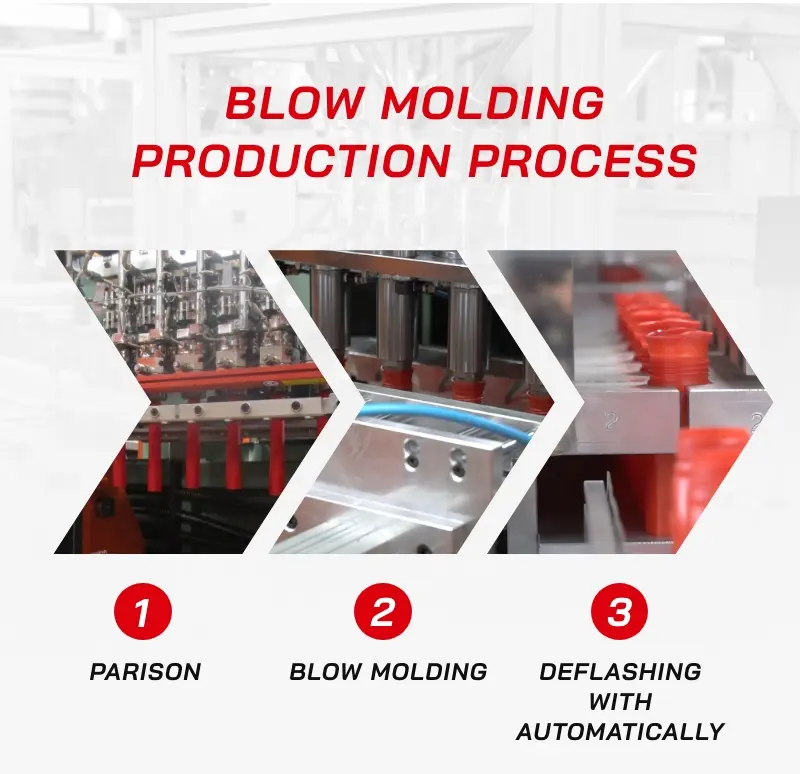

Production Procedure

As a dedicated blow molding machine manufacturer in Taiwan, FULL SHINE holds an ISO 9001 Certificate and complies with the CE standard. These international standards ensure that our product quality is reliable. To provide premium-quality machines, each step in the manufacturing process is designed using CAD, 3D Inventor, and SolidWorks. We strive to offer meticulous service through innovative design and quality-assured machines.

FULL SHINE offers high-quality blow molding machines, ensuring a productive and efficient production line.