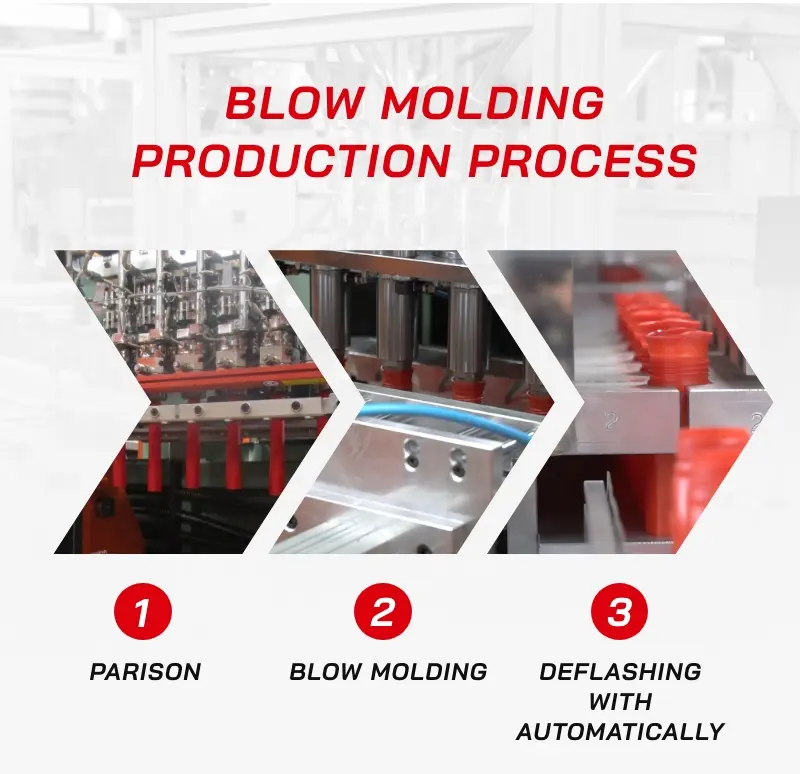

Blow molding is a manufacturing process used to produce hollow plastic parts, such as bottles, containers, and tanks. While the blow molding machine itself is central to the process, a range of peripheral equipment plays a critical role in ensuring efficient, high-quality, and automatically production. These auxiliary devices support material loading, cooling, trimming, recycling, and automation, ultimately enhancing productivity and product quality.

- Peripheral equipment for blow molding includes:

- Material loading Systems

- Chillers and Cooling Systems

- Air Compressors and Air Dryers

- Trimming and Deflashing Units

- Mold Temperature Controllers

- Grinders and Crushers

- Robot arm and Automation Systems

The integration of these peripheral devices with blow molding machines enables manufacturers to operate more efficiently, reduce downtime, and improve the overall quality of their products.