PET Stretch Blow Molding Machine

"Our FS-4000AD PET stretch blow molding machine is specially designed for PET bottle making, the machine operate with pneumatic production and equipped with 4 cavities mold for production line, the max production output is up to 4000 pices per hour.

With high quality, durable components, and excellent cooling system, this machine will incerease efficiency and lower labour cost."

Apply for mineral water bottles,shampoo bottles, and so on.

- Full Shine's PET Stretch Blow Molding Machine is an advanced machine for mass production.

- From feeding preform to finish blowing are fully automatic, mass production and labor cost be tremendously saved.

- This machine is also equipped with touch screen for the operator to adjust each function easily.

- Applicable Types

Mineral Water, CSD, Seasonings, Carbonated Drinks, Tea, Juice, Distilled Water, Alcoholic Beverages, Cooking Oil, Cleaning Agents, Cosmetics, household products. - Pneumatic Version

Automatic perform feeding, heating, and blowing system.

Patent chain adjustment for easy repair and maintenance.

All-purpose heating design that can be applied to different products.

Touch-screen interface, allowing easy operation.

Modular design for easy repair and maintenance.

Cost-saving for increased competitiveness.

Small floor footprint.

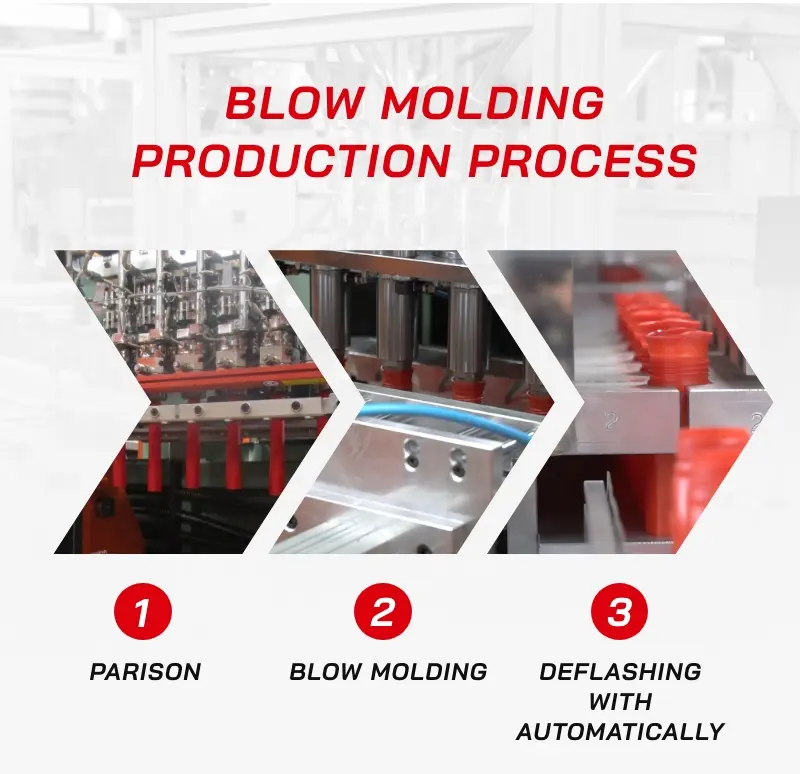

How PET (Polyethylene Terephthalate) Stretch Blow Molding Machines Work

Preform Loading: PET preforms, which are tubes of PET resin formed in the shape of a bottle, are loaded into the machine's preform hopper.

Heating: The preforms are heated in an infrared oven or a heating tunnel. Heating softens the PET material, making it malleable for the stretching and blowing processes.

Stretching: Once the preforms reach the desired temperature, they are transferred to the stretch blow molding station. Here, a stretch rod grips the neck of the preform while another mechanism stretches the preform lengthwise. This stretching ensures that the bottle will have the desired dimensions once blown.

Blowing: After stretching, the preform is moved to the blowing station where compressed air is injected into the preform. This causes it to expand and take the shape of the mold cavity. The mold determines the final shape and size of the bottle.

Cooling: Once the bottle has been formed, it is cooled to set its shape. This can be done using cold air or water cooling depending on the machine's design.

Ejection: After cooling, the finished bottles are ejected from the mold cavity. They can then be collected for further processing or packaging.

These steps are typically automated and controlled by a computerized system to ensure consistent quality and production efficiency. Additionally, modern machines may include features such as multiple cavities to produce multiple bottles simultaneously, as well as quality control systems to monitor the process and detect any defects in the finished bottles.