Automatic Extrusion Blow Molding Machines

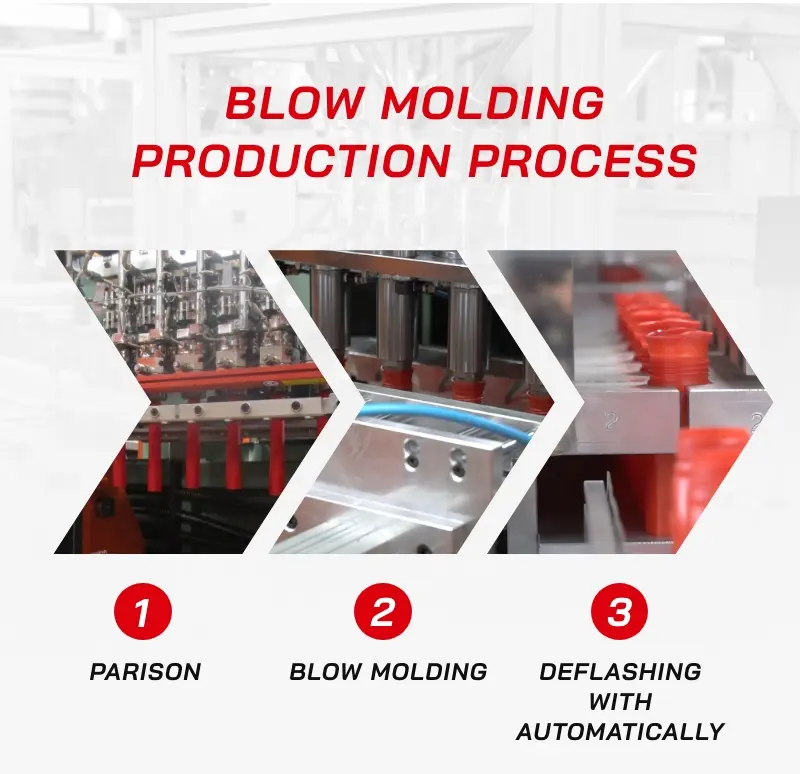

An extrusion blow molding machine is designed to produce a wide range of plastic containers and hollow parts. It’s ideal for mass production, offering an efficient and cost-effective solution for producing containers with simple shapes, such as bottles for beverages and cleansers. The process involves extruding a thermoplastic molten tube named parison, which is then inflated with compressed air inside a closed mold to form hollow objects.

FULL SHINE specializes in designing and manufacturing high-performance automatic blow molding machines. In our product series, the co-extrusion blow molding machine is perfect for producing multi-layer containers. Moreover, the co-extrusion technology combines different materials in one parison, producing end products with distinct features in each layer. For example, a bottle features a barrier layer inside with a glossy finish, enhancing both functionality and aesthetics. This advanced technology provides high-quality containers with distinct features that are tailored to your production needs.