Automatic Continuous Automatic Blow Molding Machine (Strong Clamping Design)

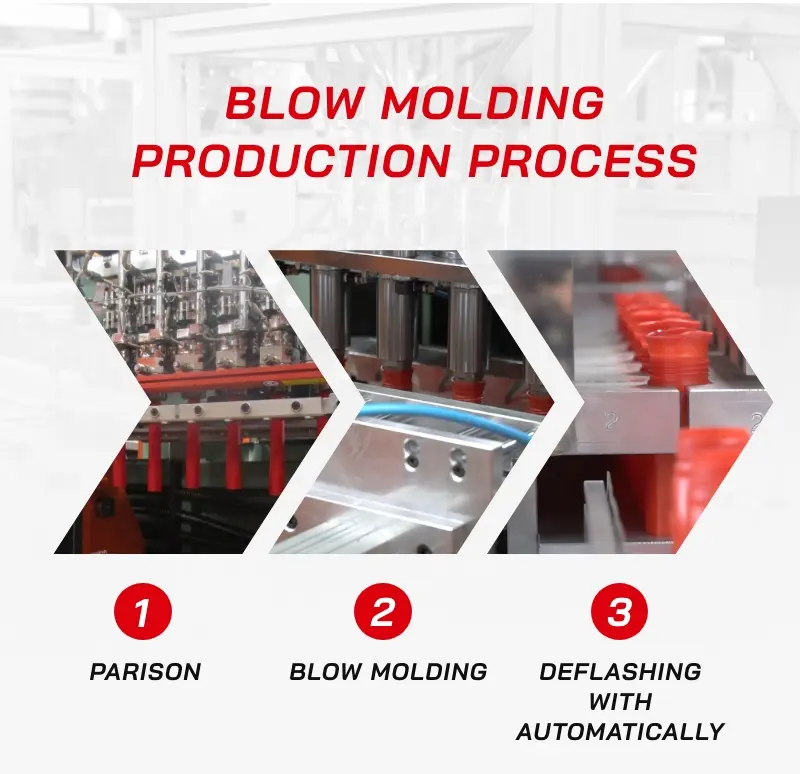

Automatic blow molding machine is a versatile and efficient tool for producing a wide variety of plastic products. It can produce products with a volume of 20ml to 30L, and is available in single-station or double-station configurations. The machine is compatible with a variety of plastic materials, including PE, PP, PETG, PVC, ABS, PA, PS, and co-extrusion materials. Automatic blow molding machine also supports hybrid system, parison control, auto deflashing, and turnkey solution. This makes it a great choice for businesses that need to produce high-quality products with precise dimensions in a cost-effective and efficient manner.

- Curved arms for strong mold clamping, equipped with linear slide guideway, made in Germany for swift movement.

- Screw drive in the control of direct-mounted gear box and inverter motor as power saving feature.

■ Die head unit with head-lifted device for cutting melted material swiftly and for easy alignment adjustment. - HMI touch screen (10.4”) from Japan, Fuji, Incorporating with PLC System for Easy Maintenance.

■ Blowing unit driven by hydraulic motor for changing mold easily-- innovative design.

■ Blowing unit, capable of equipping pre-lift feature to form small bottle neck. - Equipped with auto cutting device, conveyor, parison wall thickness controller as option.

■ High-efficient plasticizing extrusion screw for processing materials completely.

■ Full shine special-designed brake system for the carriage to provide stable movement and swift positioning.

■ Close-loop system with servo motor and servo circuit for mold carriage movement, as option.

- Apply for single station/ double station

- Production volume: from 20ml-30L

- Mono layer and multi layers are available

- Cavities: 1~12 cavities

- Apply for PE/PP/PETG/PVC/ABS/PA/ PS/ Co-extrusion material

- Option: view stripe line

- Support: Hybrid system, Parison control, auto deflashing, turn key solution

Sample Bottles

Linear and Parallel Function of Mold Carriages

Curved Arm Design for Mold Clamping

Double Station

Finish Bottle Coming Out from Machine Operation

Six Die Head with Double Station Blow Molding Machine

Single Die Head, Single Station Blow Molding Machine with Cold Cutter

Three Die Head, Double Station, Co-extrusion 2-Layer with View Stripe Blow Molding Machine

Machine Appearance

PHOTOS

Inside View of FS-90PLDO, 90mm Screw, Six Die Head, Double Station Blow Molding Machine

Photo of PLC Control Panel

Photo of PLC Control Panel

Inside View of FS-75PSDO, 75mm Screw, Single Die Head, Double Station

Inside View of FS-75PSDO, Single Die Head, Double Station

Machine Appearance

Photo of PLC Control Panel