Top 6 Blow Molding Examples by Extrusion Blow Molding Machines

Top 6 Blow Molding Examples by Extrusion Blow Molding Machines

There are lots of plastic products produced by extrusion blow molding, which is a manufacturing process that forms hollow plastic parts. In general, there are three main types of blow molding includes extrusion blow molding, injection blow molding (one stage), and injection stretch blow molding (two stages).

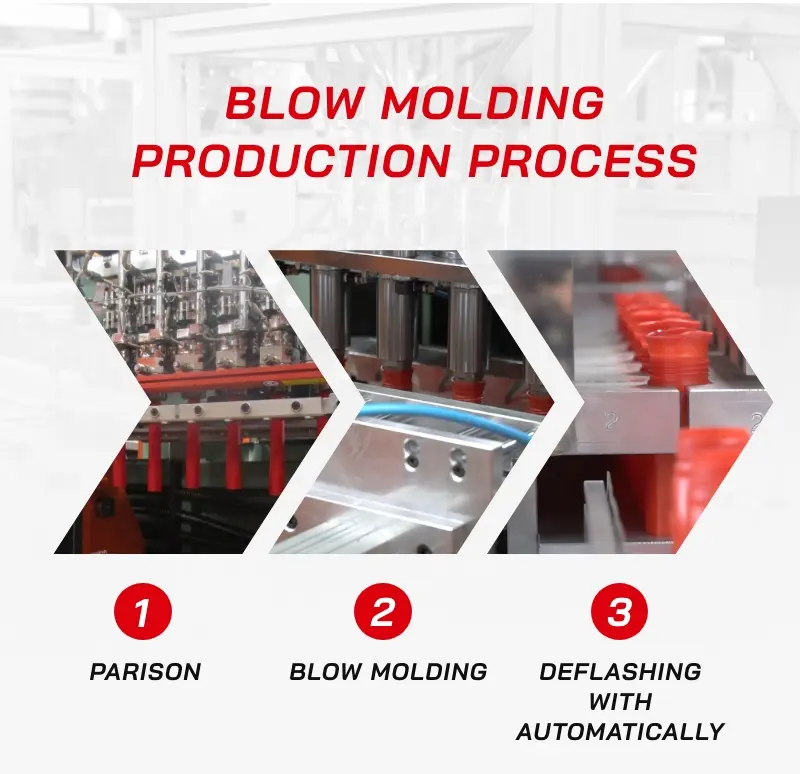

Extrusion Blow Molding Process

In the process of extrusion blow molding process (EBM), plastic material is melted and extruded into a hollow tube, and then the parison is formed. This plastic parison is then being closed into a cooled metal mold. Next, the parison is inflated with compressed air, forming the shape of the hollow container or part. After the plastic part is properly cooled, it will be ejected from the open mold.

Products made by extrusion blow molding machines are mostly milk or water bottles, shampoo bottles, automotive air ducts, jerry cans, and hollow industrial preform parts such as drums or other containers.

Extrusion Blow Molding Examples

We categorized the blow-molded parts by their function and application. Here are the top 6 categories of blow-molded products:

Food and Dairy

Water bottles, beverage bottles, and food packaging are made by blow molding machines with high-speed, producing over 2000 bottles per hour. They are the most common plastic molding products in the market.

Households

Blow molding machines can produce household and detergent bottles, laundry bottles, liquid soap plastic bottles, and lotion bottles. Most household products made by blow molding machines are made from materials including PC, PET, PP, and HDPE.

Pharmaceutical / Cosmetics

More and more pharmaceutical, health care, personal care, and cosmetic bottles are manufactured by blow molding machines. A large range of plastic blow-molded bottles and jars is available in sizes from 200ml to 10L.

Lubricants / Petrochemicals

Many lubricants and petrochemical products are stored in blow-molded containers, such as plastic fuel tanks, petrochemical tanks, oil bottles, storage tanks, etc. The multilayered PET containers are often used to store contaminated lubricants and petrochemicals.

Automotive

Blow molding is widely used in the automotive industry, making the mass production of automotive parts simple and cost-effective.

Construction / Gardening / Outdoor Products

Construction barrels, watering pots, and plastic outdoor furniture made by blow molding machines deliver a strong and durable weather-resistant structure.

Read more about watering pot extrusion blow molding machine.

Here is the video showing more details about blow molding and products produced by extrusion blow molding machines:

Read more Application of Blow Moulding.

The Main Differences Between Extrusion Blow Molding and Injection Blow Molding

- Process:

The process of extrusion blow moulding involves forming a parison and then blowing. Whereas the process of injection blow moulding involves injection and blowing, then ejecting the final output. - Mold Cost:

The price for extrusion blow molding is lower than injection blow molding. - Production Time:

Production time for the extrusion blow moulding process is slower than the injection moulding process. - Scrap / Flash:

More scraps are produced when using extrusion blow molding machines. - Flexibility of Product Thickness:

The thickness of extrusion blow moulding products can be adjusted, but it is limited in injection moulding.

Read more Injection Blow Molding Machine - Key for Perfect Injection Blow Molding Parts.

Plastic products made from extrusion blow molding machines play a vital role in our lives. It would be difficult and inconvenient to live without them.

High-quality plastic extrusion blow molding products require exceptional blow molding machines. Full Shine Plastic Machinery offers various customized blow molding machines for our customers. Especially in the mold and tooling details for extrusion blow molding, we can offer a reliable solution for different demands. Customers can begin with an idea or a design of finished goods, then we can streamline all processing, and end up with a complete and quality plastic blow molding machine in order to save their cost and time.

Full Shine Plastic Machinery is not only a manufacturer and supplier of blow molding machines, but also a turnkey manufacturer. Customers won’t suffer from the time-consuming process of managing different vendors and schedules. One blow molding machine can produce many types of products with various designs cost-effectively. Full Shine’s capabilities provide a one-stop solution for your blow molding needs, maximizing your efficiency and saving you money!

Choose Full Shine Plastic Machinery to process any your plastic products

Full Shine Machinery has 28 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with molds, die heads, and auxiliary equipment. Please contact us to learn more about our capabilities.

If you want to know more about our other products, please check the link below:

Plastic Bottle Blow Molding Machines

To keep updated about the latest news of Full Shine Machinery, please follow us on our social media channels: