FULL SHINE Launches New All-Electric Mini Blow Molding Machine, Redefining Efficiency in Extrusion Blow Molding

FULL SHINE, a Taiwanese manufacturer with 33 years of expertise in extrusion blow molding technology, proudly announces the launch of its latest all-electric mini blow molding machine. This new model represents a major breakthrough in continuous extrusion shuttle systems, delivering a smarter, cleaner, and more efficient solution for plastic container production.

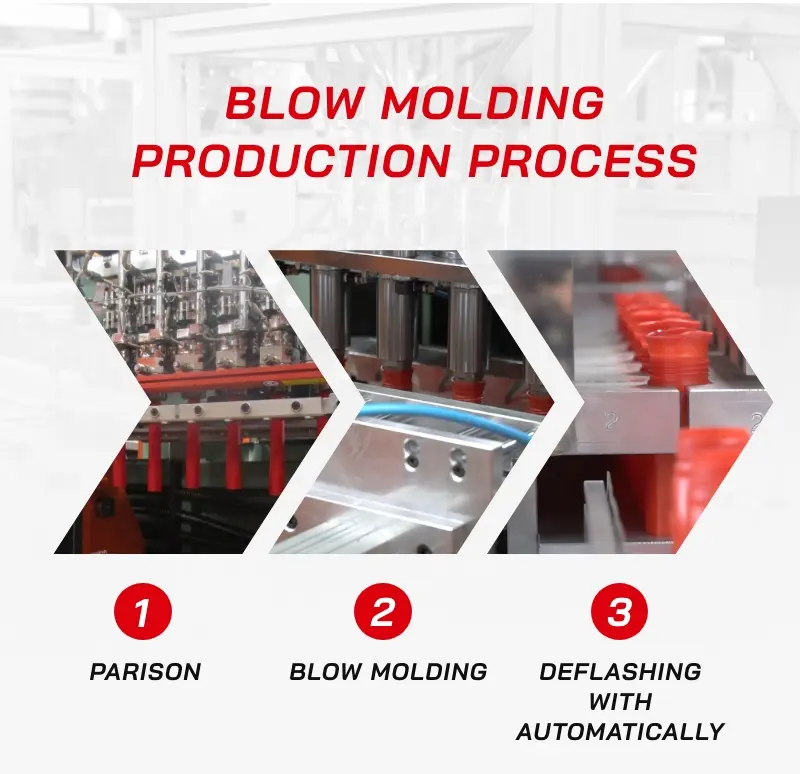

Designed and manufactured entirely in Taiwan, the all-electric machine eliminates traditional hydraulic systems and adopts a fully servo-driven architecture. By combining energy efficiency, mechanical precision, and low maintenance requirements, the machine ensures stable, reliable, and repeatable performance throughout the entire blow molding process.

All critical motion components—including the mold holder, clamping unit, die head, and blowing system—are driven by high-performance Taiwanese-made servo motors and gearboxes. The servo-controlled clamping system provides smooth, linear, and perfectly symmetrical mold movement, resulting in superior container quality and enhanced machine stability.

With a compact base frame and an optimized modular layout, the machine offers excellent accessibility for mold changes, cleaning, and routine maintenance. This thoughtful design makes the all-electric mini blow molding machine especially suitable for flexible manufacturing environments where frequent mold changes are required.

All equipment from Full Shine Plastics machinery complies with the latest European safety and electrical standards. Key die head components are developed in-house, while major parts are sourced from trusted suppliers in Germany, Japan, and Taiwan, ensuring consistent quality and long-term reliability. Localized production further guarantees complete quality traceability and stable delivery.

The product lineup includes single-station and dual-station configurations, covering applications from small bottles to medium-sized 5-liter plastic drums. Machines can be equipped with extruders ranging from 30 mm to 65/24D in diameter, delivering plasticizing capacities of up to 55 kg per hour, and supporting PE, PP, and co-extruded multilayer materials.

Guided by the concept of “more efficient, more precise, quieter, and more sustainable,” FULL SHINE’s all-electric mini extrusion blow molding machine sets a new benchmark for energy-saving technology. It reflects the company’s deep industry experience, innovative spirit, and commitment to excellence—while showcasing the reliability and craftsmanship of Taiwanese manufacturing on the global stage.

For more information about FULL SHINE, please visit: https://www.full-shine.com/