Highlights & Advantages of PET 2-Stage Stretch Blow Molding Machine

Highlights & Advantages of PET 2-Stage Stretch Blow Molding Machine

PET 2-Stage Stretch Blow Molding Machine – The Ultimate Bottle-Making Solution

Are you looking for a reliable, high-performance machine for PET bottle manufacturing? Our PET 2-Stage Stretch Blow Molding Machine is designed to deliver outstanding quality and flexibility to meet a wide range of packaging needs. Whether it's beverages, edible oils, cosmetics, or pharmaceuticals, this machine guarantees bottles with excellent clarity, strength, and consistency every time.

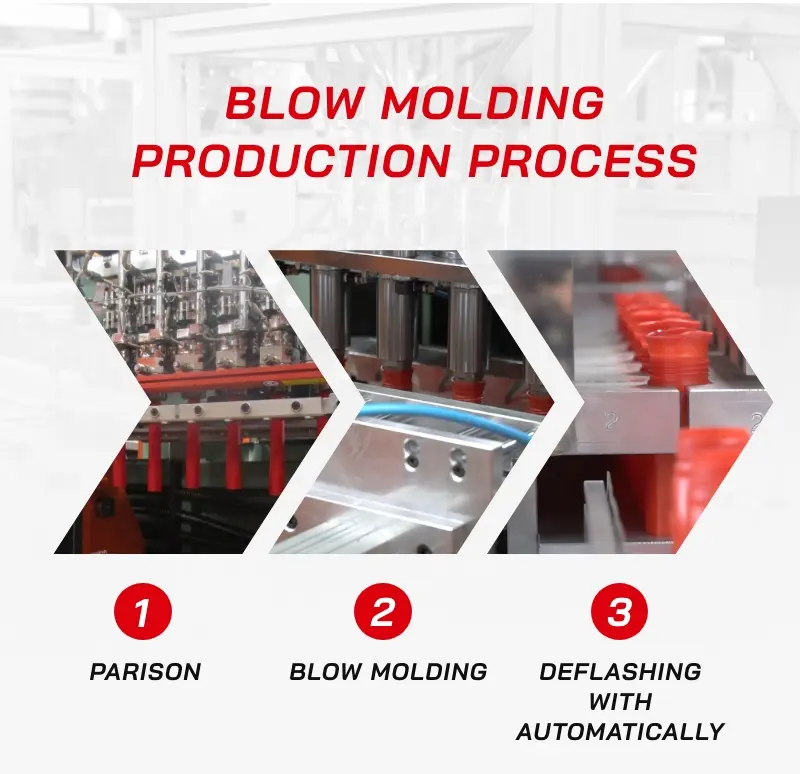

How It Works – Precision at Every Stage

The 2-stage process is engineered for maximum efficiency and accuracy:

Injection Molding:

PET preforms are precisely crafted with finished necks and threads, ensuring perfect cap compatibility.

Stretch Blow Molding:

Preforms are reheated to an optimal temperature, stretched with a high-strength rod, and blown with high-pressure air to form flawless bottles that match the mold shape exactly.

Key Features of PET 2-Stage Stretch Blow Molding Machine

High Production Quality

- Produces bottles with excellent clarity, strength, and consistency.

- Good wall thickness distribution due to controlled stretching and blowing.

Flexibility in Bottle Design

- Accommodates complex shapes and various sizes (from small vials to large containers).

- Ideal for customized packaging.

Energy Efficiency (Compared to Single-Stage in some cases)

- Machines with advanced infrared heating systems optimize energy consumption, contributing to lower operating costs and a reduced carbon footprint.

- Precise temperature control prevents energy waste.

Long Lifespan & Low Maintenance

- Built with high-quality components for durability and reliability.

- Modular design allows for easy access and quick part replacement, minimizing downtime.

User-Friendly Operation

- Equipped with intuitive PLC control systems and touchscreens for easy parameter adjustments and real-time monitoring.

- Automated processes reduce the need for constant manual intervention.

Separate Preform Production

- Allows for outsourcing or using stock preforms, reducing complexity in operations.

- Preforms can be stored, transported, and reused, increasing logistical flexibility.

Future Trends of PET Products

Sustainability & Recycling:

With growing global emphasis on environmental protection, PET bottles are increasingly designed for recyclability and lighter weight, reducing material consumption and carbon footprint.

Bio-based PET (Bio-PET):

The shift towards plant-derived PET is gaining momentum, offering an eco-friendly alternative without compromising performance.

Smart Packaging:

Integration of intelligent labels, QR codes, and IoT features will enhance product traceability and consumer engagement.

Premium & Custom Shapes:

Demand for unique bottle designs, higher clarity, and premium finishes is driving innovations in blow molding technology.

High-Speed Automation:

Future machines will emphasize greater automation, energy efficiency, and AI-based quality control to meet large-scale, cost-effective production needs.