One Step Injection Blow Molding Machine - One of the 3 Keys to Achieving the Perfect Injection Blow Molding Parts

One Step Injection Blow Molding Machine - One of the 3 Keys to Achieving the Perfect Injection Blow Molding Parts

POSTED JANUARY 2021

There are lots of plastic parts in our daily life manufactured by One-Step Injection Blow Molding (IBM). Especially blow molded bottles and containers, which are some of the most common plastic parts. In the world of manufacturing, the One-Step Injection Blow Molding Machine is the main key to achieving the perfect injection blow molding parts.

One-Step Injection Blow Molding Machine

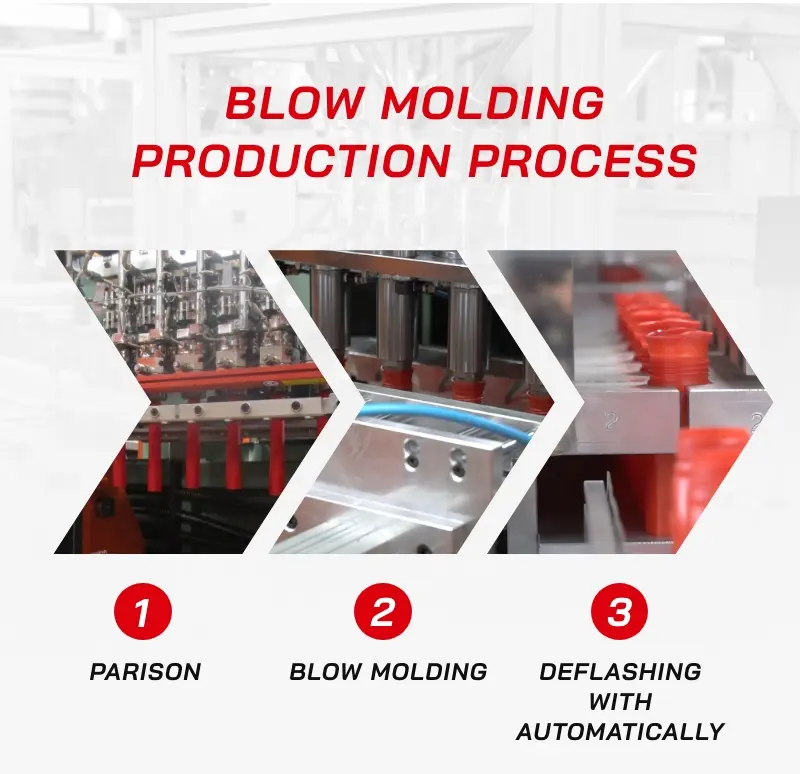

One-Step Injection Blow Molding Machine (IBM) is used for mass production of small medical and single serve bottles. There are three stations of the Injection Blow Molding process: injection, blowing and ejection. One-Step Blow Injection consists of an extruder barrel and screw assembly which melt the polymer. The molten polymer is fed into a hot runner manifold where it is injected through nozzles into a heated cavity and core pin. The cavity mold forms the external shape and is clamped around a core rod, which forms the internal shape of the preform. The preform consists of a fully formed bottle/jar neck with a thick tube of polymer attached, which will form the body. The preform mold opens, and the core rod is rotated and clamped into the hollow, chilled blow mold. The end of the core rod opens and allows compressed air into the preform, which inflates it into the finished shape. After a cooling period, the blow mold opens, and the core rod is rotated to the ejection position. The finished part is stripped off the core rod, and as an option, can be leak-tested prior to packing. The preform and blow mold typically have three to sixteen cavities, depending on the part size and the required output. In the whole process, there are three sets of core rods which allow concurrent preform injection, blow molding and ejection.

Advantages of One-Step Injection Blow Molding Machine

Efficient Production

As mentioned above, the product is made in one cycle (From Injecting Preforms to Blowing Bottles). It is ideal for the mass production of injection blow molded parts, especially bottles and containers.

User-Friendly Controller

One Stage Injection Blow Molding Machine is equipped with a fully computerized touch screen, which is easy to operate.The self-diagnostics system in the touch screen displays instant erroneous messages, which help the engineers to figure out the problem immediately.

Environmentally Friendly and Energy Saving

While producing the product, there is zero contamination and no need for an extra heater to be implemented in the machine. The In-Mold heating preconditioning feature and zero contamination will improve your branding image.

Cost-Saving

The cost-saving can be divided into two parts. Labor Cost: The machine has fully automatic operation, and together with the user-friendly touch screen, so less manpower is needed. Material Cost: While operating, there are basically zero burrs and flash. So the material usage is maximized.

Easy Availability of Replacement Parts

Replacement parts, such as the Pneumatic and Hydraulic components of the Injection Blow Molding machines, can be easily acquired in local markets.

Product Diversity and Increasing Value

One-stage injection Blow Molding Machines are suitable for making all types of nice-looking, small-volume bottles for different industries like pharmaceutical, cosmetics, and household industries.

Parts and Products of One-Step Injection Blow Molding Machine

Food and Dairy

Beverage bottles, Milk bottles, Yogurt drinks, and food packaging are made by One Stage Injection Blow Molding Machines with high-speed capacities of over 3,000 pcs bottles per hour.

Households Industry

Small volume bottles like detergent bottles, laundry bottles, liquid soap bottles, and lotion bottles which require shiny, flawless surface, are the most common molded Injection Blow Molding Parts in hotels and our daily life.

Pharmaceutical / Cosmetics Industry

Most pill bottles and cosmetics bottles require precise size necks and other dimensions. The One Stage Injection Blow Molding Machine again is the perfect match for this industry. A large range of refined and essential designed plastic blow molded bottles, all are available from size from 5ml to 2L.

For more other Blow Molding Products and Examples, please refer to TOP 6 BLOW MOLDING EXAMPLES

One-Step Injection Blow Molding Machine Video

Molds for One-Step Injection Blow Molding Machine

The Injection Blow Mold is the second key for achieving the perfect Injection Blow Molding Parts. The Injection Blow Mold is to forms the external shape and is clamped around a core rod which forms the internal shape of the preform. The weight, thickness, other dimensions, and volume are included in the design before making the mold. A good matched mold ensures high precision necks and threads of Injection Blow Molded Parts.

To make a good match, choosing a good manufacturer of an IBM One-Step Injection Blow Molding Machine that is able to offer customized mold tests is highly recommended. The Injection Blow Mold test steps are:

- According to the properties of the raw materials used in the finished product and the size of the mold, an appropriate mold temperature controller is selected to increase the temperature of the mold to the temperature required for production. After the mold temperature is increased, it is necessary to check the movement of each part again, because the steel may cause the mold to get stuck after thermal expansion, so pay attention to the sliding of each part to avoid strain and vibration.

- According to the different raw materials, use a moderate dry raw material. Try to use the same raw materials as much as possible for mass production in the future. Try NOT to trial the mold completely with reground materials. If there is a color requirement, you can arrange the color test together.

- Problems such as internal stress often affect the secondary processing. After the mold is tested, the finished product should be stabilized, and then the secondary processing should be performed.

- After the mold is closed at a slow speed, adjust the mold closing pressure and perform several actions to check whether the mold is closed. Use unequal pressure to avoid burrs and mold deformation in the finished product.

Materials for One-Step Injection Blow Molding Machine

Different types of plastic resins and materials offer unique benefits. To understand and choose an Injection Blow Molding Materials to fit for your project is the third key for achieving the perfect Injection Blow Molding Parts. Injection Blow Molded Parts can be formed from a wide range of plastic resins and materials, including: PP(polypropylene), PE(polyethylene), HDPE(High Density Polyethylene), LDPE(Low Polyethylene) and PS(polystyrene).

Choose Full Shine Plastic Machinery to process any your plastic products

Full Shine Machinery has 28 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with Molds, Die Heads, and Auxiliary Equipment. Please contact us to learn more about our capabilities.

If you want to know more about our other products, please check the link below:

https://www.full-shine.com/one-step-injection-blow-molding-machines

To keep updated about the latest news of Full Shine Machinery, please follow us in our Social Media Channels:

- Full Shine YouTube Channel:

https://www.youtube.com/channel/UCEqOofSPN-0nljuc8WyG-uQ - Full Shine Facebook Channel:

https://www.facebook.com/pages/category/Industrial-Company/FULL-SHINE-PLASTIC-MACHINERY-CO-LTD-Plastic-Blow-Molding-Machinery-218537074843577/