How Blow Molding Machines Drive Sustainable Manufacturing

With global restrictions on plastic usage tightening, new approaches to production are being adopted to align with environmental priorities. Many have shifted toward sustainable manufacturing to comply with environmental standards, cut expenses, and strengthen their brand image. At the core of this transformation, blow molding machines enable eco-conscious production through improved material efficiency, streamlined workflows, and reduced ecological impact. To grasp how these goals are being met, it helps to start with the basics of blow molding technology.

Blow Molding Basics and Industry Role

Blow molding is a process widely used to form hollow plastic products. Common in industries like packaging, automotive, and consumer goods, blow molding machines shape plastics efficiently and at scale. As plastic remains vital to modern life, blow molding has become integral to global production systems. Its ability to produce lightweight, durable, and cost-effective containers has made it essential to fast-moving industries seeking both performance and affordability.

Blow Molding and Sustainable Manufacturing

Blow molding supports sustainability by enabling manufacturers to reduce material use, manage waste efficiently, and integrate recycled content without sacrificing performance or output.

Material Efficiency and Recycling

Optimization of materials using is critical in reducing the environmental impact of manufacturing. Blow molding machines facilitate using recyclable plastics like HDPE and PET, alongside bio-based resins. Advanced multi-layer co-extrusion technology integrates recycled materials, minimizing waste and promoting the circular economy. Moreover, lightweight product strategies are increasingly adopted, significantly reducing overall plastic usage.

For instance, Nestlé continues to prioritize packaging environmental performance through lighter-weight bottle designs and expanded use of recycled PET. Ongoing progress includes adopting lighter packaging formats and increasing the use of recyclable materials across product lines. These steps reflect a broader industry shift toward minimizing plastic dependency while aligning with regulatory expectations and sustainability goals.

Waste Management and Circular Economy

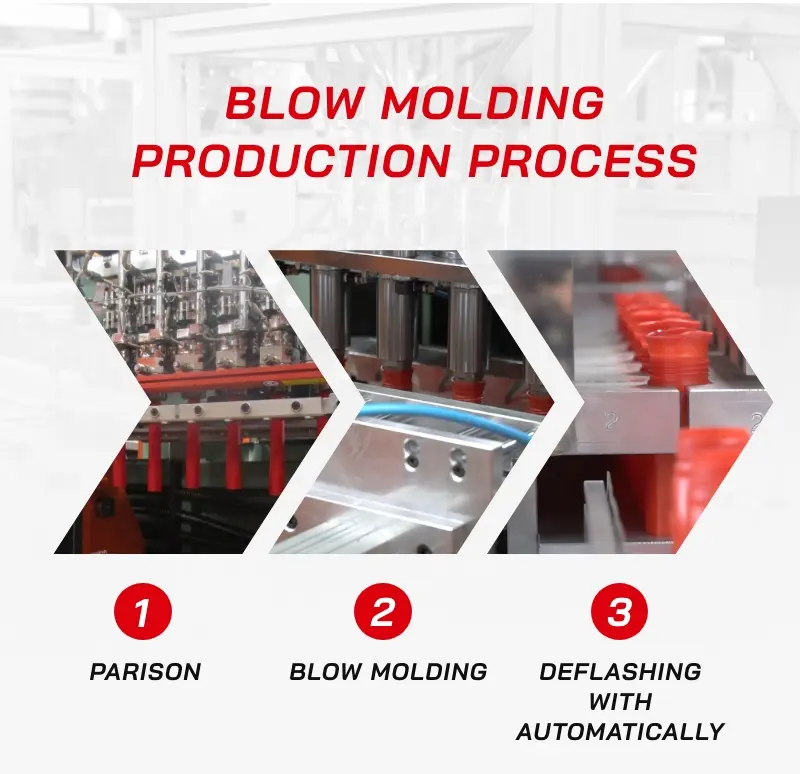

Effective waste management is central to a circular economy, and blow molding machines contribute significantly by minimizing production waste and enabling its reintegration into the production cycle. During the blow molding process, excess material known as "flash" or "trim" is produced as molds close around the parison. Advanced systems now include automated deflashing units that remove this material, which is then conveyed to in-line regrinding equipment and processed into reusable flakes or pellets.

These reground materials can be blended with virgin resin and fed directly back into the machine to form new containers, maintaining product quality while reducing raw material demand. This closed-loop system reduces landfill waste, conserves resources, and aligns with broader goals of energy conservation and emission reduction. When combined with lightweight, recyclable product designs and planned material distribution, blow molding becomes a highly optimized solution that meets both environmental and operational objectives.

Optimizing Production Processes

Modern blow molding machines feature sophisticated automation and control systems that optimize processes while reinforcing sustainability targets. These technologies manage key factors such as temperature, pressure, and timing with precision, ensuring consistent results and minimizing production errors.

With integrated sensors and real-time monitoring, adjustments can be made instantly to avoid waste and downtime. Together with smart manufacturing platforms, these tools enable streamlined, adaptive, and environmentally aligned production environments.

How Blow Molding Creates Environmental and Economic Value

Building on these technical advancements, the broader impact of sustainable manufacturing becomes evident. It delivers measurable environmental progress while driving long-term cost efficiency, forming a strong foundation for wider operational and market gains.

Environmental Impact

By reducing plastic waste and supporting recycled materials such as rPET (recycled Polyethylene Terephthalate) and rPP (recycled Polypropylene), blow molding machines play a direct role in mitigating environmental footprint. These systems help lower greenhouse gas emissions throughout the product lifecycle by decreasing reliance on virgin plastics and minimizing waste. Additionally, energy-efficient machine designs that employ fully electric or hybrid servo motors contribute to reduced carbon footprint and reinforce long-term emissions reduction goals.

Economic Advantages

Implementing sustainable practices with blow molding not only protects the environment but also reduces operational costs. Lower material and energy expenses, reduced labor costs, and efficient use of space all translate into significant savings. Moreover, the ability to deliver high-quality, eco-friendly products strengthens competitiveness in sustainability-focused markets, especially as rising climate awareness fuels demand for lower-impact alternatives. Automation and intelligent systems also enable quicker production cycles and better responsiveness, enabling leaner operations and greater overall efficiency.

Consumer Approval

Environmental awareness plays a growing role in shaping consumer behavior. As more people evaluate the ecological impact of their purchases, a clear preference is emerging for products made through sustainable methods. Advanced blow molding technologies facilitate this shift by enabling the production of environmentally responsible packaging. When sustainability is reflected in product design and manufacturing, it contributes to stronger brand recognition, deeper trust, and greater consumer loyalty, all of which reinforce long-term brand value and visibility in the market.

Real-world Case Study

One real-world setup in Pakistan features a three-layer blow molding machine used to produce 20-liter containers. They used a strategic material composition: 20% virgin PE, 60% recycled PE (rPE), and another 20% virgin PE. The intermediate recycled layer maximized the use of sustainable materials without compromising container quality. Production waste was continuously recycled back into the middle layer, achieving resource efficiency, reducing raw material costs, and maintaining compliance with environmental regulations.

Global brands like Coca-Cola and Unilever similarly utilize eco-conscious practices, integrating high proportions of recycled plastics into packaging, achieving regulatory compliance, and significantly reducing their environmental impact.

Source:

https://www.cocacolaep.com/sustainability/this-is-forward/packaging/

https://www.unilever.com/sustainability/plastics/

Future Trends in Blow Molding Technology

Future developments in blow molding machines will be influenced by sustainability goals, intelligent manufacturing, automation, customization demands, and evolving global regulations.

1. Digital Twin Technology

Emerging digital twin technology will become central to blow molding equipment. By simulating real-time conditions and analyzing production data, energy consumption, downtime, and product quality can be optimized without extensive physical prototyping.

2. Regulatory Compliance and ESG Goals

Stricter global environmental regulations, such as the EU’s Packaging and Packaging Waste Regulation (PPWR), are reshaping blow molding equipment design. Machines will increasingly support high-content recycled materials and feature advanced emission control systems to ensure compliance and meet ESG targets.

3. IoT Integration

Integrating IoT technology will further advance streamlined production. Real-time monitoring, precise control, and predictive maintenance enabled by IoT systems contribute to superior resource management and lower operational costs. These technologies also help reduce environmental footprints, supporting corporate sustainability initiatives.

Conclusion

Blow molding machines are key in achieving sustainable manufacturing. With strategic use of recyclable materials, efficient waste management, and process optimization, it becomes possible to significantly lower environmental impacts, reduce costs, and attract eco-conscious consumers. Embracing future technologies, like Digital Twins and IoT, will ensure continued sustainability gains.

Full Shine's blow molding machines support multi-layer configurations, diverse materials, and stable mold carriage movement for efficient, high-quality production. To implement these sustainable practices effectively, consider advanced blow molding solutions from us. For more information, contact us today!