What is a blow molding machine?

1.What is a blow molding machine?

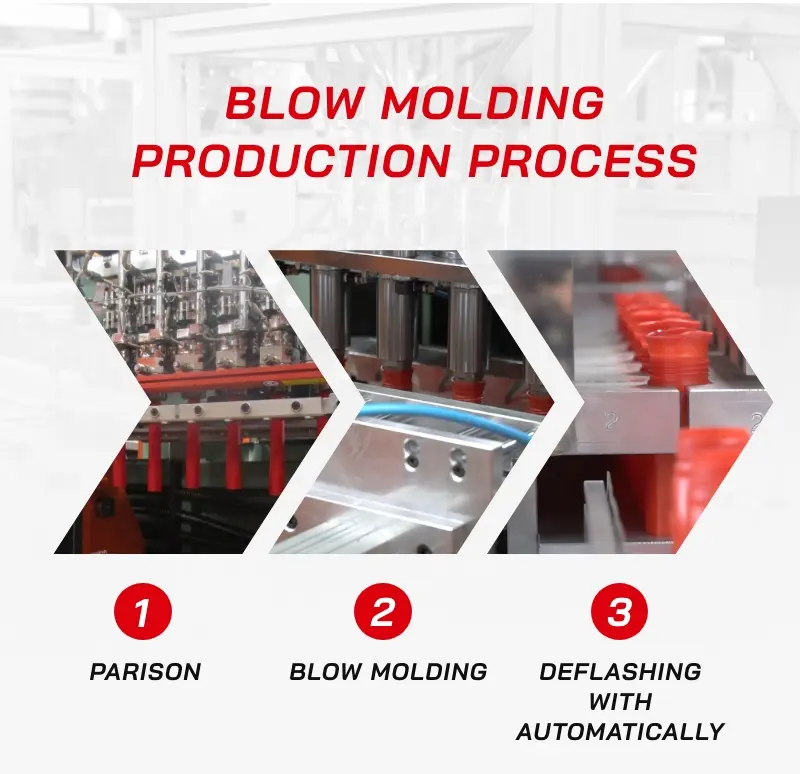

A blow molding machine is a type of equipment used to produce plastic products (including bottles, cans, barrels, drums and so on ). It melts and mixes plastic resin granules in a screw and barrel set through heating, extrudes them into a hollow plastic parison, and then uses pressurized air to blow mold it into a pre-set shape. Blow molding machines are widely used in beverage, food, cosmetics, pharmaceuticals, daily necessities, and containers across various industries, and their products can be seen everywhere.

2.What are the main types of blow molding machines?

Blow molding machines are mainly divided into the following types:

- Fully automatic PP/PE blow molding machine: The entire process, from melting and feeding the raw plastic, heating, blow molding to finished product removal, is automated. Suitable for automated integrated production, it is highly efficient and has low labor costs.

- Automatic Accumulator Blow Molding Machine: This machine is used to manufacture hollow plastic products (such as chemical drums, water tanks, water towers, automotive parts, float and so on). Its key feature is that the molten plastic is first extruded through an extruder and temporarily stored in an accumulator ( die head) to form a certain quantity (parison). Then, it is rapidly extruded into a mold all at once and blown into shape with compressed air. It is particularly suitable for producing medium to large-sized products, offering advantages such as high throughput, excellent thickness control (a thickness controller is required), and relatively low mold costs.

- Semi-automatic PET blow molding machine: Requires manual feeding of the PET preform into the heating machine and manual removal after blow molding. Suitable for applications with small production volumes or frequent mold changes.

- Fully automatic PET blow molding machine: The entire process, from automatically loading the PET preform, heating, blow molding to finished product removal, is automated. Suitable for large-scale production, it is highly efficient and has low labor costs.

- Fully Automatic One-Stage Injection Molding (Stretch) Machine: From the initial melting and feeding of raw PE/PP/PS/PC plastic, heating, first injecting a preform and then continuing blow molding to the removal of the finished product, the entire process is automated, generating no excess waste. Suitable for integrated automated production, it offers high efficiency and low labor costs.

3.Plastic products have brought numerous benefits and conveniences to modern society.

However, improper disposal of waste packaging has transformed these benefits into serious environmental problems.

Today, most laws and regulations aim to regulate the "conscious and efficient use of plastics to reduce environmental pollution." From the perspective of a circular economy, reducing plastic use and promoting recycled design have become inevitable trends. Reducing carbon emissions and reducing plastic use are common goals for the future.

Countries such as the EU and the US have mandated that beverage bottles and other plastic products must contain a certain proportion of PCR (post-consumer recycled PET) recycled materials.

The use of PCR and RPET plastics in the production of plastic products—PCR and RPET being "post-consumer recycled PET"—is a process from recycled PET (PET bottles, beverage bottles, etc.) after consumer use. This material undergoes sorting, washing, crushing, and granulation processes to create new environmentally friendly packaging, bottles, textiles, etc., achieving the recycling of plastics, reducing dependence on virgin petroleum, and is a key environmentally friendly material for achieving a circular economy and corporate ESG environmental goals.