Accumulator Head Blow Molding Machine (Front Take-out)

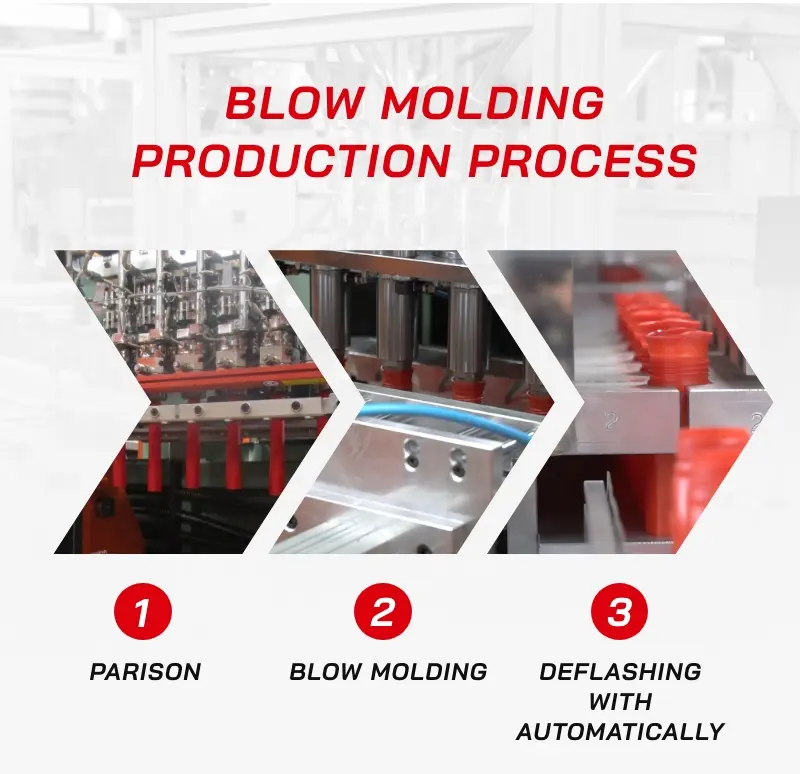

As an intermittent extrusion blow molding machine, the FS-90LSSO Accumulator Head Blow Molding Machine is designed for high-precision production. Intermittent extrusion blow molding is a process in which the parison is extruded in distinct cycles, rather than continuously. By intermittently extruding parisons with large volume, it allows controlled pauses between each cycle, enabling precise shaping. It is ideal for manufacturing high-volume containers with detailed geometries.

The FS-90LSSO is an accumulator head blow molding machine designed for high-precision, large-volume production of containers with intricate shapes, featuring intermittent extrusion, advanced temperature control, and energy-efficient components. Below are the key features that help this blow molding machine achieve an advanced machining process.

Key features

Advanced die head design

This blow molding machine stores a great deal of molten plastic in the accumulator-type mold head before extruding the parison, which forms a large container after inflating. The accumulator head features a First-In-First-Out system (FIFO), ensuring the material first transferred into the accumulator will also be extruded first. This system makes sure the parison is pushed out completely for advanced structural integrity.

Precise parison control

It is equipped with multi-point parison controllers, ensuring accurate control of parison thickness, providing precise shape control. Moreover, the hydraulically adjustable platen can move vertically and horizontally to suit various mold sizes, which is ideal for producing large and irregular-shaped items like picnic tables, air ducts, and automotive parts. The FS-90LSSO delivers outstanding efficiency and precision for high-volume production.

Efficient extrusion system

The FS-90LSSO utilizes a screw and barrel made from nitrogen-treated steel, offering enhanced heat resistance for long-term reliability. It also features a high-efficiency mixing screw, paired with a German-made gearbox and a Japanese inverter that allows adjustable screw speed, while reducing hydraulic oil consumption by up to 40% compared to conventional systems, ensuring efficient and consistent extrusion. Additionally, the machine is equipped with a hydraulic injection piston and cylinder, enabling faster material accumulation and quicker color changes to support high-mix, high-volume production demands.

User-friendly safety system

To ensure safe and efficient operation, the machine features a user-friendly design. The intuitive LCD touch screen paired with a Fuji 10.4” color HMI control panel allows operators to easily manage settings, temperature, and receive real-time error messages. With memory for up to 50 product configurations, it streamlines setup for repeat production. The system is also equipped with comprehensive protective measures, such as light curtains, electric eye sensors, and safety gates.

Contact us for more information about the exceptional machines and customized options!

- Mold opening/closing via German linear slide ways for smooth, accurate movement.

- Supports bottom and side blowing and features a pneumatic parison enlarger for uniform shape, which is ideal for large containers from 30 to 50 liters.

- Uses YUKEN hydraulic valves with proportional flow and pressure control.

- Optional automatic robot arms feature a water-cooling design that prevents sticking and handling heavy products.

- Optional Full Shine oil cleaner extends oil lifespan.

- Apply for single station

- Production volume: from 10L-1000L

- Cavities: 1 cavity

- Apply for PE/PP /ABS/PA…

- Support: Hybrid system, Parison control, turn key solution