Automatic Continuous Automatic CO-Extrusion Blow Molding Machine

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

- Curved arms for strong mold clamping, equipped with linear slide guideway, made in Germany for swift movement.

- Screw drive in the control of direct-mounted gear box and inverter motor as power saving feature.

■ Die head unit with head-lifted device for cutting melted material swiftly and for easy alignment adjustment. - HMI touch screen (10.4”) from Japan, Fuji, Incorporating with PLC System for Easy Maintenance.

■ Blowing unit driven by hydraulic motor for changing mold easily-- innovative design.

■ Blowing unit, capable of equipping pre-lift feature to form small bottle neck. - Equipped with auto cutting device, conveyor, parison wall thickness controller as option.

■ High-efficient plasticizing extrusion screw for processing materials completely.

■ Full shine special-designed brake system for the carriage to provide stable movement and swift positioning.

■ Close-loop system with servo motor and servo circuit for mold carriage movement, as option.

- Apply for single station/ double station

- Production volume: from 20ml-30L

- Mono layer and multi layers are available

- Cavities: 1~12 cavities

- Apply for PE/PP/PETG/PVC/ABS/PA/ PS/ Co-extrusion material

- Option: view stripe line

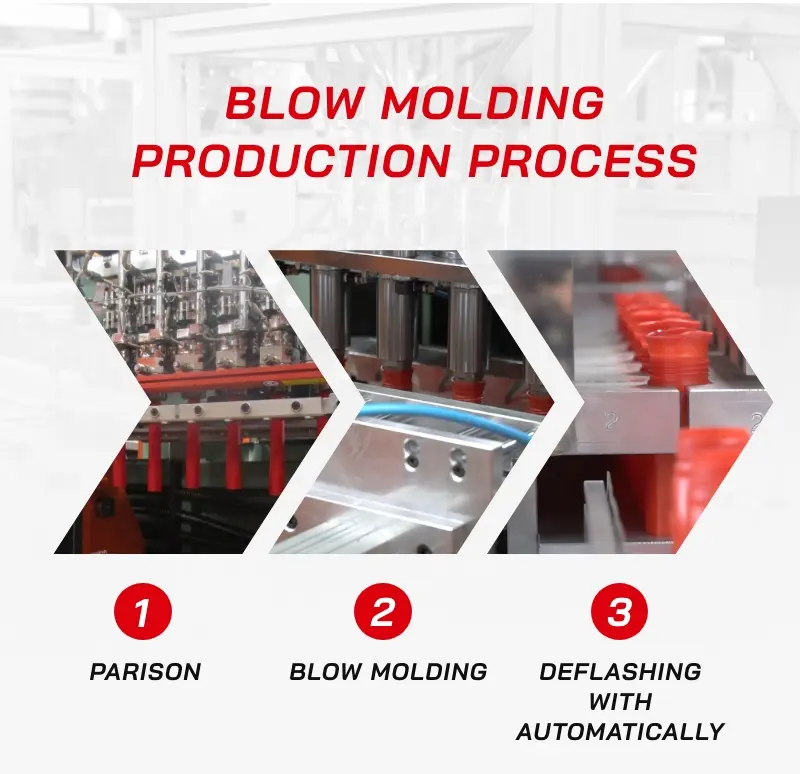

- Support: Hybrid system, Parison control, auto deflashing, turn key solution

Top View Side of Co-extrusion 2 Layers Blow Molding Machine

2 Layers Co-extrusion Bottles with View Stripe Line

Machine Photo of Co-extrusion 2 Layers Blow Molding Machine

2 Layers Co-extrusion Double Die Head

Blow Pin Unit

Barrel and Screw Set with Fans

2 Layers Co-extrusion Double Die Head

Top View Side of Co-extrusion 2 Layers Blow Molding Machine

3 Layers Co-extrusion Double Die Head

3 Layers Co-extrusion Double Die Head with Hot Cutter