3 Minutes to Understand Co Extrusion Blow Molding - Machine, Process and Advantages

3 Minutes to Understand Co Extrusion Blow Molding - Machine, Process and Advantages

We use plastic products every day. From a bottle of water to a container of cleansers, plastic products play a vital role in our lives. However, have you ever wondered how these essential products are made? One of the answers is the co-extrusion blow molding technology.

What is CO Extrusion Blow Molding?

Co-extrusion blow molding is one of the most widely used techniques in the plastics industry. It can machine various plastic materials, including HDPE, PVC, PP, and PC. Co-extrusion blow molding is also commonly utilized in the production of multi-layer bottles.

Process of CO Extrusion Blow Molding – Steps by Steps

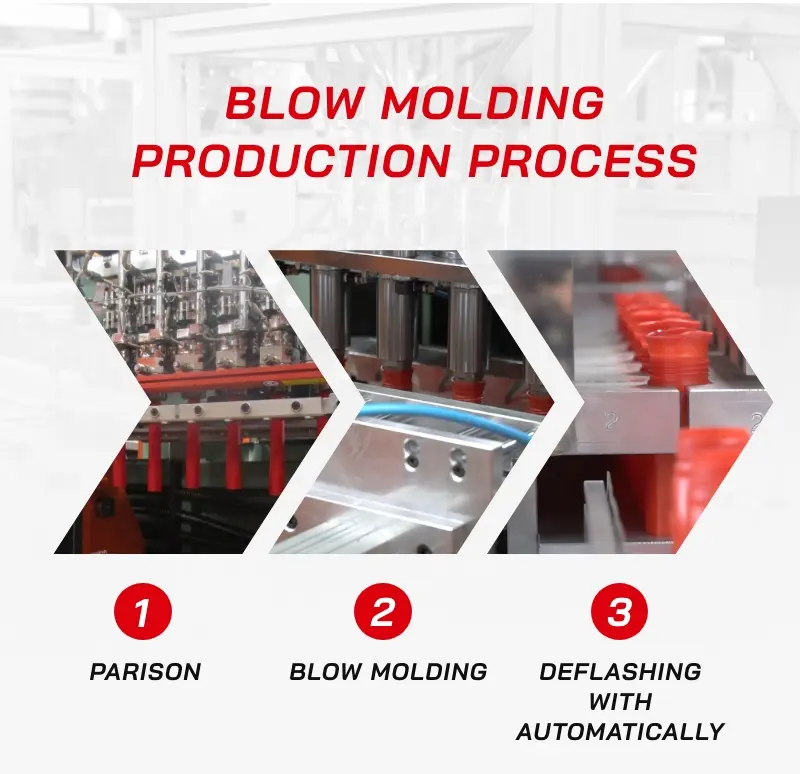

- A hot tube contains plastic material, also called parison, dropped from an extruder and reaches the water-cooled mold.

- As the mold closes, the compressed air is injected from the top or the bottom parts of the container. Then, the air blows it up just like a balloon. When the material touches the wall of mold, it is then frozen to maintain its shape.

- Bottles produced via co-extrusion blow molding machine generate top and bottom flash, which is the excess plastic material that forms around the mold. The flash should be further removed and trimmed in the sub-mold to avoid affecting the product quality. For handled bottles, the flash should be removed via an auto deflashing device or manually.

- The containers are now finished after the processes. Based on the usage of the bottle, it should further go through other tests, such as leak detection.

CO Extrusion Blow Molding Machine

Co-extrusion blow molding machine implements the extrusion blow molding (EBM) technique. It manufactures a wide range of plastic containers made from materials like HDPE, PVC, PP, PC, and so on. To be more functional, the machine can also produce multi-layer bottles, such as bottles for chemical and agricultural products. FS-40PDDL-75, the latest model from Full Shine Plastic Machinery, is an excellent example. It is an automatic, continuous extrusion blow molding machine, capable of producing up to 6-layer containers. To further get more information about FS-40PDDL-75, please visit the product page to have a closer look.

Read more about Different Types of CO Extrusion Blow Molding Machine.

CO Extrusion Blow Molding vs. Injection Blow Molding: What's the Difference?

After knowing the manufacturing process of co-extrusion blow molding, you may be curious about its differences from injection blow molding (IBM). That’s another dominant blow molding technique in the manufacturing industry. Let us then take a look at the four major differences between EBM and IBM clearly from the table below:

| EBM Extrusion Blow Molding | IBM Injection Blow Molding | |

|---|---|---|

| Co-extrusion | Available. | Not available. |

| Cost | Low tooling cost but high unit cost. | High tooling cost but low unit cost. |

| Product Outlook | With flash and scraps, but the neck needs to be trimmed. | No flash and scraps, but with an accurately finished neck. |

| Mold & Product Flexibility | High mold flexibility. | Low mold flexibility. |

| Part Thickness | Depends on how the material is stretched during blowing. | Depends on the mold and the core. |

For more detailed information on the injection blow molding machine(IBM), please visit the link below: Injection Blow Molding Machine

Advantages of CO Extrusion Blow Molding

As per the advantages of choosing EBM for production, its benefits are listed below:

- Low initial mold tooling costs.

- Flexibility of tooling. The molds can accommodate interchangeable neck finishes.

- Container sizes can range from less than 30 mL to 200 liters.

- Container shape is not restricted. The bottles can be long and flat or have handles.

- Wide selection of machinery. The tooling can be specifically geared to package volume requirements.

CO Extrusion Blow Molding Products and Applications

As EBM is one of the most commonly used techniques in plastic container production, there is a wide range of industries that implement this technique. Here are the top six industries below:

- Food and Dairy

- Households

- Pharmaceutical/cosmetics

- Lubricants/petrochemicals

- Automotive

- Constructing/garden/outdoor supplies

For more detailed information on EBM application, please visit link below: Blow Molding Examples and Products

Co Extrusion Blow Molding Machine Manufacturer - Full Shine Plastic Machinery

Until 2021, Full Shine has more than 29 years of experience specializing in blow molding machines, molds, die heads, and auxiliary equipment. Despite the challenges brought by the COVID-19 outbreak, Full Shine continues to provide high-quality machines and considerate service to our global business partners. If you have inquiries about plastic products manufacturing machines or want to know more details, please do not hesitate to contact us. Full Shine looks forward to serving you.

If you want to know more about our products, please check the product page.

To keep updated about the latest news of Full Shine Machinery, please follow us on our social media channels: