Automatic Blow Molding Machine P Series

Descripton

- ● Apply for single station/ double station

- ● Production volume: from 20ml-30L

- ● Mono layer and multi layers are available

- ● Cavities: 1~12 cavities

- ● Apply for PE/PP/PETG/PVC/ABS/PA/ PS/ Co-extrusion material

- ● Option: view stripe line

- ● Support: Hybrid system, Parison control, auto deflashing, turn key solution

Automatic blow molding machine is a versatile and efficient tool for producing a wide variety of plastic products. It can produce products with a volume of 20ml to 30L, and is available in single-station or double-station configurations. The machine is compatible with a variety of plastic materials, including PE, PP, PETG, PVC, ABS, PA, PS, and co-extrusion materials. Automatic blow molding machine also supports hybrid system, parison control, auto deflashing, and turnkey solution. This makes it a great choice for businesses that need to produce high-quality products with precise dimensions in a cost-effective and efficient manner.

- Features

- Machine Model

- Single Die-head/Single Station

- Double Die-head/Single Station

- Three Die-head/Single Station

- Four Die-head/Single Station

- Single Die-head/Double Station

- Double Die-head/Double Station

- Three Die-head/Double Station

- Single Die-head Single Station Viewstripe

- Double Die-head Single Station Viewstripe

- PHOTOS

- Video

- Features

- Curved arms for strong mold clamping, equipped with linear slide guideway, made in Germany for swift movement.

- Screw drive in the control of direct-mounted gear box and inverter motor as power saving feature. ■ Die head unit with head-lifted device for cutting melted material swiftly and for easy alignment adjustment.

- HMI touch screen (10.4”) from Japan, Fuji, Incorporating with PLC System for Easy Maintenance. ■ Blowing unit driven by hydraulic motor for changing mold easily-- innovative design.

- Equipped with auto cutting device, conveyor, parison wall thickness controller as option. ■ High-efficient plasticizing extrusion screw for processing materials completely.

■ Blowing unit, capable of equipping pre-lift feature to form small bottle neck.

■ Full shine special-designed brake system for the carriage to provide stable movement and swift positioning.

■ Close-loop system with servo motor and servo circuit for mold carriage movement, as option.

| EXPOSITION OF FULL SHINE'S MACHINE MODEL |

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE | |

|---|---|---|---|---|---|

| FS- | 40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| 45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors | |

| 55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | ||

| 65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | ||

| 75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | ||

| 80 | (I) Lateral | (L) Six Layers | |||

| 90 | (V) View Stripe | ||||

| 100 | (P) PC baby bottle | ||||

| Example | |||||

| FS- | 65 | P | D | S | D |

| MODEL | FS-40 PSSO | FS-45 PSSO | FS-55 PSSO | FS-65 PSSO | FS-75 PSSO | FS-90 PSSO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 40 | 45 | 55 | 65 | 75 | 90 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 | 15-56 |

| Inveter motor(HP) | 5 | 7.5 | 10 | 15 | 25 | 40 |

| Oil hydraulic drive motor(HP) | 5 | 7.5 | 10 | 10 | 15 | 30 |

| Optional air compressor(HP) | 5 | 5 | 7.5 | 7.5 | 10 | 15 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 4-6 | 5-7 | 5-7 | 6-8 |

| Clamping force(Ton) | 2.8 | 3.9 | 4.4 | 6.9 | 10 | 5.2 |

| Oil tank capacity(Gallon) | 38 | 55 | 60 | 80 | 120 | 250 |

| Nunber of heaters(ZONE) | 4 | 4 | 4 | 5 | 5 | 7 |

| Heating capacity(KW) | 7 | 9.5 | 12.5 | 16.8 | 18 | 20.5 |

| Total installed power(KW) | 15 | 21 | 30 | 43.5 | 48 | 62 |

| Extruding capacity per hour(kg/hr) | 15 | 24 | 36 | 55 | 75 | 100 |

| Dry cycle per hour(time/hr) | 1285 | 1030 | 880 | 720 | 650 | 650 |

| Product capacity(c.c./L) | 15-500 | 60-1000 | 150-2500 | 500-5000 | 5L-10L | 10L-20L |

| Product weight(g.) | 5-40 | 10-100 | 20-170 | 40-280 | 200-370 | 500-900 |

| Min./Max. diameter of product(m/m) | 10-75 | 20-100 | 30-140 | 50-200 | 80-260 | 150-340 |

| Extruding mouth outer diameter(m/m) | 50 | 56 | 80 | 150 | 200 | 280 |

| Mold center distance(m/m) | * | * | * | * | * | * |

| Clamping distance(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 | 160-670 |

| Length of mold capacity(m/m) | 100-210 | 146-266 | 155-590 | 160-380 | 223-426 | 288-556 |

| Width of mold capacity(m/m) | 200 | 300 | 320 | 430 | 480 | 560 |

| Machine net weight(kg) | 2500 | 3000 | 3500 | 4400 | 7300 | 8300 |

| Machine dimension(m) | 2.3*1.4*2.2 | 3*1.4*2.3 | 3*1.5*2.3 | 3.2*1.6*2.6 | 4.2*1.7*2.7 | 4.1*1.9*3.6 |

| MODEL | FS-40 PDSO | FS-45 PDSO | FS-55 PDSO | FS-65 PDSO | FS-75 PDSO | FS-90 PDSO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 40 | 45 | 55 | 65 | 75 | 90 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 | 15-58 |

| Inveter motor(HP) | 5 | 7.5 | 10 | 15 | 25 | 60 |

| Oil hydraulic drive motor(HP) | 5 | 7.5 | 10 | 10 | 15 | 30 |

| Optional air compressor(HP) | 5 | 5 | 7.5 | 7.5 | 10 | 15 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 | 5-7 | 6-8 |

| Clamping force(Ton) | 2.8 | 3.9 | 4.4 | 6.9 | 10 | 5.2 |

| Oil tank capacity(Gallon) | 38 | 55 | 60 | 80 | 120 | 250 |

| Nunber of heaters(ZONE) | 6 | 6 | 7 | 8 | 8 | 11 |

| Heating capacity(KW) | 7 | 10.25 | 13.6 | 17.5 | 19 | 33 |

| Total installed power(KW) | 15.5 | 22 | 29.5 | 37 | 50 | 67 |

| Extruding capacity per hour(kg/hr) | 15 | 24 | 36 | 55 | 75 | 100 |

| Dry cycle per hour(time/hr) | 1285 | 1030 | 880 | 720 | 650 | 650 |

| Product capacity(c.c./L) | 15-200 | 50-500 | 100-1250 | 280-1800 | 0.5L-2.5L | 1L-5L |

| Product weight(g.) | 4-25 | 5-40 | 10-100 | 20-170 | 40-170 | 80-280 |

| Min./Max. diameter of product(m/m) | 10-65 | 20-70 | 30-85 | 40-100 | 40-130 | 100-160 |

| Extruding mouth outer diameter(m/m) | 38 | 42 | 50 | 65 | 80 | 150 |

| Mold center distance(m/m) | 85 | 100 | 120 | 140 | 160 | 180 |

| Clamping distance(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 | 160-670 |

| Length of mold capacity(m/m) | 100-210 | 146-266 | 155-590 | 160-380 | 223-426 | 288-556 |

| Width of mold capacity(m/m) | 200 | 300 | 320 | 430 | 480 | 560 |

| Machine net weight(kg) | 2600 | 3200 | 3700 | 4600 | 7500 | 8500 |

| Machine dimension(m) | 2.3*1.4*2.2 | 3*1.4*2.3 | 3*1.5*2.3 | 3.2*1.6*2.6 | 4.2*1.7*2.7 | 5.2*1.9*3.5 |

| MODEL | FS-40 PTSO | FS-45 PTSO | FS-55 PTSO | FS-65 PTSO | FS-75 PTSO | FS-90 PTSO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 40 | 45 | 55 | 65 | 75 | 90 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 | 15-58 |

| Inveter motor(HP) | 5 | 7.5 | 10 | 15 | 25 | 60 |

| Oil hydraulic drive motor(HP) | 5 | 7.5 | 10 | 10 | 15 | 30 |

| Optional air compressor(HP) | 7.5 | 7.5 | 10 | 10 | 15 | 20 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 | 5-7 | 6-8 |

| Clamping force(Ton) | 2.8 | 3.9 | 4.4 | 6.9 | 10 | 5.2 |

| Oil tank capacity(Gallon) | 38 | 55 | 60 | 80 | 120 | 250 |

| Nunber of heaters(ZONE) | 8 | 8 | 9 | 10 | 10 | 11 |

| Heating capacity(KW) | 8.5 | 12 | 15 | 19.3 | 21.5 | 42.8 |

| Total installed power(KW) | 16.5 | 23.5 | 32 | 39 | 52.5 | 88 |

| Extruding capacity per hour(kg/hr) | 15 | 24 | 36 | 55 | 75 | 100 |

| Dry cycle per hour(time/hr) | 1250 | 1000 | 850 | 720 | 650 | 650 |

| Product capacity(c.c./L) | 10-125 | 20-325 | 40-825 | 100-1000 | 180-1500 | 1L-3L |

| Product weight(g.) | 3-10 | 5-25 | 10-50 | 10-90 | 15-145 | 80-200 |

| Min./Max. diameter of product(m/m) | 10-45 | 20-55 | 30-55 | 30-80 | 30-95 | 60-110 |

| Extruding mouth outer diameter(m/m) | 30 | 37 | 40 | 55 | 80 | 98 |

| Mold center distance(m/m) | 75+75 | 85+85 | 100+100 | 120+120 | 120+120 | 180+180 |

| Clamping distance(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 | 160-670 |

| Length of mold capacity(m/m) | 100-210 | 146-266 | 155-590 | 160-380 | 223-426 | 288-556 |

| Width of mold capacity(m/m) | 200 | 300 | 320 | 430 | 480 | 560 |

| Machine net weight(kg) | 2800 | 3400 | 3900 | 4900 | 7900 | 8900 |

| Machine dimension(m) | 2.3*1.4*2.2 | 3*1.4*2.3 | 3*1.5*2.3 | 3.2*1.6*2.6 | 4.2*1.7*2.7 | 5.2*1.9*3.5 |

| MODEL | FS-45 PFSO | FS-55 PFSO | FS-65 PFSO | FS-75 PFSO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 55 | 65 | 75 | 90 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 15-60 | 15-60 | 15-58 | 15-58 |

| Inveter motor(HP) | 15 | 20 | 30 | 60 |

| Oil hydraulic drive motor(HP) | 10 | 15 | 15 | 30 |

| Optional air compressor(HP) | 15 | 15 | 20 | 20 |

| Air pressurer(kg/cm2) | 6-8 | 6-8 | 6-8 | 6-8 |

| Clamping force(Ton) | 4.4 | 6.9 | 10 | 5.2 |

| Oil tank capacity(Gallon) | 60 | 80 | 120 | 250 |

| Nunber of heaters(ZONE) | 11 | 13 | 13 | 11 |

| Heating capacity(KW) | 16.5 | 20.8 | 25.7 | 42.8 |

| Total installed power(KW) | 37.5 | 48 | 61 | 88 |

| Extruding capacity per hour(kg/hr) | 36 | 55 | 75 | 100 |

| Dry cycle per hour(time/hr) | 750 | 750 | 650 | 650 |

| Product capacity(c.c./L) | 30-200 | 100-500 | 300-1000 | 500-2500 |

| Product weight(g.) | 10-25 | 10-40 | 15-90 | 40-170 |

| Min./Max. diameter of product(m/m) | 20-55 | 30-55 | 30-90 | 30-90 |

| Extruding mouth outer diameter(m/m) | 37 | 42 | 50 | 75 |

| Mold center distance(m/m) | 85+85+85 | 85+85+85 | 180+180+180 | 180+180+180 |

| Clamping distance(m/m) | 140-410 | 150-540 | 160-670 | 160-670 |

| Length of mold capacity(m/m) | 155-290 | 160-380 | 243-466 | 288-556 |

| Width of mold capacity(m/m) | 430 | 480 | 520 | 560 |

| Machine net weight(kg) | 4100 | 5200 | 8300 | 9300 |

| Machine dimension(m) | 3.1*1.8*2.3 | 3.2*1.9*2.6 | 4.3*2*2.7 | 5.2*3.1*3.5 |

| MODEL | FS-40 PSDO | FS-45 PSDO | FS-55 PSDO | FS-65 PSDO | FS-75 PSDO | FS-90 PSDO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 45 | 55 | 65 | 75 | 90 | 100 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 28/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 15-62 | 15-60 | 15-60 | 15-58 | 15-56 | 20-65 |

| Inveter motor(HP) | 7.5 | 10 | 15 | 30 | 75 | 75 |

| Oil hydraulic drive motor(HP) | 7.5 | 10 | 10 | 15 | 30 | 40 |

| Optional air compressor(HP) | 10 | 15 | 15 | 20 | 30 | 30 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 | 6-8 | 6-8 |

| Clamping force(Ton) | 3.9 | 4.4 | 6.9 | 10 | 5.2 | 6.5 |

| Oil tank capacity(Gallon) | 60 | 80 | 120 | 160 | 250 | 300 |

| Nunber of heaters(ZONE) | 4 | 4 | 5 | 5 | 11 | 8 |

| Heating capacity(KW) | 9.5 | 12.5 | 16.8 | 18 | 20.5 | 36 |

| Total installed power(KW) | 22 | 28 | 37 | 53 | 63 | 114 |

| Extruding capacity per hour(kg/hr) | 24 | 36 | 55 | 75 | 100 | 180 |

| Dry cycle per hour(time/hr) | 1030*2 | 800*2 | 720*2 | 650*2 | 650*2 | 480*2 |

| Product capacity(c.c./L) | 40-500 | 65-1250 | 150-2500 | 500-5000 | 5L-10L | 10L-20L |

| Product weight(g.) | 5-40 | 10-100 | 20-170 | 40-280 | 200-370 | 500-900 |

| Min./Max. diameter of product(m/m) | 10-75 | 20-100 | 30-140 | 50-200 | 100-280 | 200-300 |

| Extruding mouth outer diameter(m/m) | 56 | 80 | 150 | 200 | 280 | 420 |

| Mold center distance(m/m) | * | * | * | * | * | * |

| Clamping distance(m/m) | 130-320 | 140-410 | 150-540 | 160-670 | 160-670 | 390-750 |

| Length of mold capacity(m/m) | 146-266 | 155-290 | 160-380 | 223-426 | 288-556 | 386-640 |

| Width of mold capacity(m/m) | 300 | 320 | 360 | 430 | 520 | 560 |

| Machine net weight(kg) | 7000 | 7400 | 7900 | 8500 | 9700 | 11500 |

| Machine dimension(m) | 3*1.8*2.5 | 3*1.9*2.5 | 3.2*2*2.8 | 4.2*2.1*2.9 | 5.2*2.3*3.7 | 5.8*3.3*4 |

| MODEL | FS-40 PDDO | FS-45 PDDO | FS-55 PDDO | FS-65 PDDO | FS-75 PDDO | FS-90 PDDO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 45 | 55 | 65 | 75 | 90 | 100 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 28/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 15-61 | 15-60 | 15-60 | 15-58 | 15-56 | 20-65 |

| Inveter motor(HP) | 10 | 10 | 15 | 30 | 40 | 75 |

| Oil hydraulic drive motor(HP) | 7.5 | 10 | 10 | 15 | 15 | 25 |

| Optional air compressor(HP) | 10 | 15 | 15 | 20 | 30 | 30 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 | 6-8 | 6-8 |

| Clamping force(Ton) | 1.5 | 4.4 | 6.9 | 10 | 13 | 26 |

| Oil tank capacity(Gallon) | 60 | 80 | 120 | 160 | 250 | 300 |

| Nunber of heaters(ZONE) | 8 | 7 | 8 | 8 | 10 | 10 |

| Heating capacity(KW) | 10 | 13.6 | 17.5 | 19 | 22 | 37 |

| Total installed power(KW) | 21.5 | 30 | 38 | 54 | 65 | 113 |

| Extruding capacity per hour(kg/hr) | 32 | 36 | 55 | 75 | 100 | 180 |

| Dry cycle per hour(time/hr) | 1030*2 | 800*2 | 720*2 | 650*2 | 650*2 | 480*2 |

| Product capacity(c.c./L) | 30-200 | 40-500 | 100-1000 | 280-2000 | 700-3000 | 2L-6L |

| Product weight(g.) | 4-20 | 5-40 | 10-65 | 20-110 | 40-180 | 110-300 |

| Min./Max. diameter of product(m/m) | 10-65 | 20-70 | 30-85 | 40-110 | 50-150 | 100-220 |

| Extruding mouth outer diameter(m/m) | 42 | 50 | 65 | 80 | 150 | 200 |

| Mold center distance(m/m) | 85 | 120 | 140 | 160 | 220 | 250 |

| Clamping distance(m/m) | 130-320 | 140-410 | 150-540 | 160-670 | 160-670 | 390-750 |

| Length of mold capacity(m/m) | 146-370 | 155-290 | 160-380 | 223-426 | 288-556 | 385-640 |

| Width of mold capacity(m/m) | 300 | 320 | 360 | 430 | 520 | 560 |

| Machine net weight(kg) | 7200 | 7600 | 8200 | 9100 | 10100 | 11900 |

| Machine dimension(m) | 3*1.4*2.3 | 3.2*2*2.8 | 3.4*3*3 | 4.4*3.1*3.1 | 5.4*3.3*3.9 | 6.4*3.5*5.6 |

| MODEL | FS-45 PTDO | FS-55 PTDO | FS-65 PTDO | FS-75 PTDO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 55 | 65 | 75 | 90 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 15-60 | 15-60 | 15-58 | 15-58 |

| Inveter motor(HP) | 10 | 15 | 30 | 40 |

| Oil hydraulic drive motor(HP) | 10 | 10 | 15 | 15 |

| Optional air compressor(HP) | 15 | 15 | 20 | 20 |

| Air pressurer(kg/cm2) | 4-6 | 5-7 | 5-7 | 6-8 |

| Clamping force(Ton) | 4.4 | 6.9 | 10 | 13 |

| Oil tank capacity(Gallon) | 80 | 120 | 160 | 250 |

| Nunber of heaters(ZONE) | 9 | 10 | 10 | 12 |

| Heating capacity(KW) | 15 | 19.3 | 21.5 | 25 |

| Total installed power(KW) | 32 | 40 | 56.5 | 68 |

| Extruding capacity per hour(kg/hr) | 36 | 55 | 75 | 100 |

| Dry cycle per hour(time/hr) | 850*2 | 720*2 | 650*2 | 650*2 |

| Product capacity(c.c./L) | 15-300 | 50-600 | 100-1000 | 280-2000 |

| Product weight(g.) | 5-25 | 8-45 | 10-70 | 20-110 |

| Min./Max. diameter of product(m/m) | 10-55 | 20-70 | 30-90 | 40-90 |

| Extruding mouth outer diameter(m/m) | 40 | 55 | 80 | 98 |

| Mold center distance(m/m) | 85+85 | 100+100 | 120+120 | 120+120 |

| Clamping distance(m/m) | 140-410 | 150-540 | 160-670 | 160-670 |

| Length of mold capacity(m/m) | 155-290 | 160-380 | 233-426 | 288-556 |

| Width of mold capacity(m/m) | 320 | 360 | 430 | 520 |

| Machine net weight(kg) | 7800 | 8400 | 9400 | 10500 |

| Machine dimension(m) | 3.4*2.1*2.8 | 3.6*3.1*3 | 4.4*3.2*3.1 | 5.4*3.4*3.9 |

| MODEL | FS-45 PSSV | FS-55 PSSV | FS-65 PSSV | FS-75 PSSV | FS-90 PSSV |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 45/25 | 55/25 | 65/25 | 75/25 | 90/25 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 15-61/5-25 | 15-60/5-25 | 15-60/5-25 | 15-58/5-25 | 15-56/5-25 |

| Inveter motor(HP) | 7.5/2 | 10/2 | 15/2 | 25/2 | 60/2 |

| Oil hydraulic drive motor(HP) | 7.5 | 10 | 10 | 15 | 30 |

| Optional air compressor(HP) | 5 | 7.5 | 7.5 | 10 | 15 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 | 6-8 |

| Clamping force(Ton) | 3.9 | 4.4 | 6.9 | 9.5 | 5.2 |

| Oil tank capacity(Gallon) | 55 | 60 | 80 | 120 | 250 |

| Nunber of heaters(ZONE) | 6 | 6 | 7 | 7 | 11 |

| Heating capacity(KW) | 11.5 | 14.5 | 18.8 | 23 | 40 |

| Total installed power(KW) | 24.5 | 31.5 | 40.5 | 54.5 | 72.5 |

| Extruding capacity per hour(kg/hr) | 30 | 42 | 61 | 81 | 106 |

| Dry cycle per hour(time/hr) | 1030 | 880 | 720 | 650 | 65 |

| Product capacity(c.c./L) | 60-1000 | 150-2500 | 500-5000 | 5L-10L | 10L-20L |

| Product weight(g.) | 10-100 | 20-170 | 40-280 | 200-370 | 500-900 |

| Min./Max. diameter of product(m/m) | 20-100 | 30-140 | 50-200 | 80-260 | 50-340 |

| Extruding mouth outer diameter(m/m) | 56 | 80 | 150 | 200 | 280 |

| Mold center distance(m/m) | * | * | * | * | * |

| Clamping distance(m/m) | 130-320 | 140-410 | 150-540 | 160-670 | 160-670 |

| Length of mold capacity(m/m) | 146-266 | 155-290 | 160-380 | 223-426 | 288-556 |

| Width of mold capacity(m/m) | 300 | 320 | 430 | 480 | 600 |

| Machine net weight(kg) | 3600 | 3800 | 4700 | 7600 | 8600 |

| Machine dimension(m) | 3*1.4*2.9 | 3*1.5*2.9 | 3.6*1.6*3.2 | 4.2*1.7*3.3 | 5.38*2.45*3.43 |

| MODEL | FS-45 PDSV | FS-55 PDSV | FS-65 PDSV | FS-75 PDSV | FS-90 PDSV |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 45/25 | 55/25 | 65/25 | 75/25 | 90/25 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 15-61/5-25 | 15-60/5-25 | 15-60/5-25 | 15-58/5-25 | 15-58/5-25 |

| Inveter motor(HP) | 7.5/2 | 10/2 | 15/2 | 25/2 | 40/2 |

| Oil hydraulic drive motor(HP) | 7.5 | 10 | 10 | 15 | 15 |

| Optional air compressor(HP) | 5 | 7.5 | 7.5 | 10 | 15 |

| Air pressurer(kg/cm2) | 4-6 | 5-7 | 5-7 | 5-7 | 6-8 |

| Clamping force(Ton) | 3.9 | 4.4 | 6.9 | 9.5 | 13 |

| Oil tank capacity(Gallon) | 55 | 60 | 80 | 120 | 250 |

| Nunber of heaters(ZONE) | 8 | 10 | 10 | 10 | 12 |

| Heating capacity(KW) | 14.5 | 18.8 | 20.3 | 25 | 36 |

| Total installed power(KW) | 27.5 | 36.5 | 43 | 57 | 80 |

| Extruding capacity per hour(kg/hr) | 30 | 42 | 61 | 81 | 106 |

| Dry cycle per hour(time/hr) | 1030 | 880 | 720 | 650 | 650 |

| Product capacity(c.c./L) | 40-500 | 100-1250 | 280-1800 | 0.5L-2.5L | 1L-5L |

| Product weight(g.) | 5-40 | 10-100 | 20-170 | 40-170 | 100-160 |

| Min./Max. diameter of product(m/m) | 20-70 | 30-85 | 40-100 | 40-130 | 100-160 |

| Extruding mouth outer diameter(m/m) | 42 | 50 | 65 | 80 | 150 |

| Mold center distance(m/m) | 100 | 120 | 140 | 160 | 200 |

| Clamping distance(m/m) | 130-320 | 140-410 | 150-540 | 160-670 | 160-670 |

| Length of mold capacity(m/m) | 146-266 | 155-290 | 160-380 | 223-426 | 288-556 |

| Width of mold capacity(m/m) | 300 | 320 | 430 | 480 | 560 |

| Machine net weight(kg) | 3700 | 3900 | 4800 | 7700 | 8700 |

| Machine dimension(m) | 3*1.6*2.9 | 3*1.7*2.9 | 3.6*1.8*3.2 | 4.2*1.9*3.3 | 5.2*2.1*4.1 |

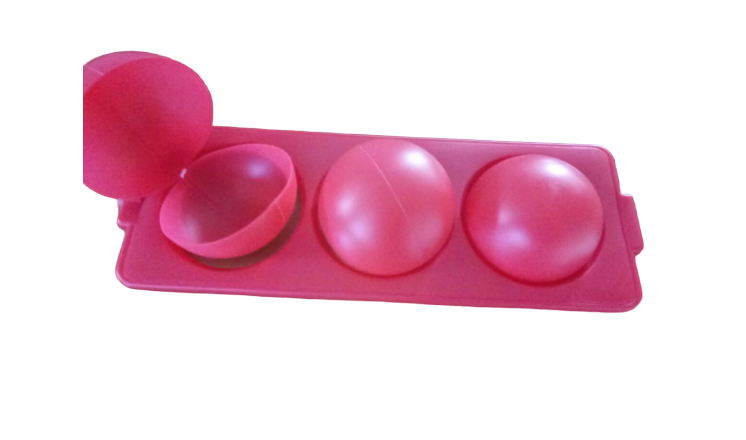

Sample Bottles

Linear and Parallel Function of Mold Carriages

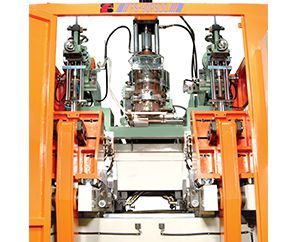

Curved Arm Design for Mold Clamping

Double Station

Finish bottle come out from machine operation

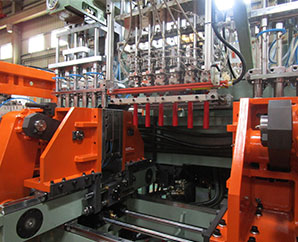

Six die head with double station blow molding machine

Single die head with single station blow molding machine with cold cutter

Three die head with double station, co extrusion 2 layers with view stripe blow molding machine

Machine outlooking

Inside photo of FS-90PLDO automatic blow molding machine, 90mm screw, Six die head with double station blow molding machine

Photo of PLC control panel

Photo of PLC control panel

Inside photo of FS-75PSDO automatic blow molding machine, 75mm screw, Single die head with double station blow molding machine

Inside photo of FS-75PSDO automatic blow molding machine, Single die head with double station blow molding machine

Machine outlooking

Photo of PLC control panel

Application

Hand washing bottle / cleaning supplies

Blow Molding Plastic Bottles

Oil bottle / oil barrel

Mask/Closed Wound Drainage Systems

Household/Cosmetics

Household/Cleaning product bottle

Household/Cosmetics

Household/Cosmetics

Closed Wound Drainage Systems

Toys

Automotive

Household/Cosmetics

Outdoor supplies/Bird balls

Household/Cleaning product bottle

Mascara bottle

Pesticide bottle

Household/Cosmetics