全自動押出中空吹氣成型機 H系列

- 特性

- 機械型號索引系列

- 單模頭/單模架

- 雙模頭/單模架

- 參模頭/ 單模架

- 肆模頭/ 單模架

- 單膜頭/雙膜架

- 雙模頭/雙模架

- 參模頭/ 雙模架

- 肆模頭/ 雙模架

- 雙層/單模頭/單模架

- 雙色/單頭單模架

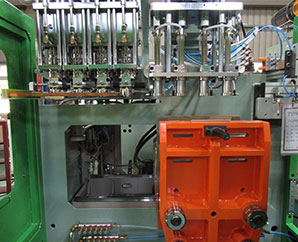

- 照片

- 影片

- 特性

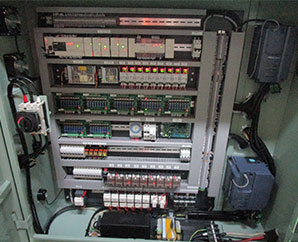

- HMI觸控式電腦螢幕(選配),搭配PLC電控系統,修改容易,方便於當地維護。

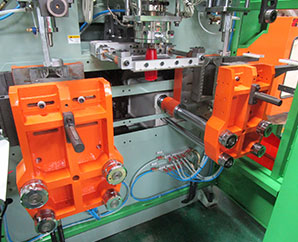

- 開閉模採用圓型鋼柱導桿形式,平移式移模以德製線型滑軌為基礎滑動運作方式。

- 螺桿傳動方式採直結式德製齒輪箱搭配變頻馬達驅動。

- 仰頭式模頭作動方式,使下料迅速,避免沾黏模具。

- 吹氣座配置快速移動變換位置功能,以油壓馬達驅動,以利模具更換、節省時間,此功能屬創新便捷設計。

| 機械型號索引系列 |

| 螺桿直徑(M/M) | 機械類別 | 模頭 | 模架 | 產品型式 | |

|---|---|---|---|---|---|

| FS- | 40 | (H) 平移式開關模採用線性滑桿 | (S) 單模頭 | (S) 單模架 | (O) 一般 |

| 45 | (P) 平行式移模 | (D) 雙模頭 | (D) 雙模架 | (C) 雙色 | |

| 55 | (O) 標準型 / 斜移式 | (T) 三模頭 | (D) 雙層 | ||

| 65 | (A) 空壓式 | (F) 四模頭 | (T) 三層 | ||

| 75 | (L) 前向取出機型 | (E) 八模頭 | (F) 四層 | ||

| 80 | (I) 側向取出機型 | (L) 六層 | |||

| 90 | (V) 視窗 | ||||

| 100 | (P) PC奶瓶 | ||||

| 範例 | |||||

| FS- | 65 | P | D | S | D |

| 型號 | FS-40 HSSO | FS-45 HSSO | FS-55 HSSO | FS-65 HSSO | FS-75 HSSO |

| 使用塑料 | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 40 | 45 | 55 | 65 | 75 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 7.5 | 7.5 | 10 | 15 | 25 |

| 幫浦驅動馬力(HP) | 5 | 7.5 | 10 | 10 | 15 |

| 選配空壓機搭配馬力(HP) | 5 | 5 | 7.5 | 7.5 | 10 |

| 空氣壓力(kg/cm2) | 4-6 | 4-6 | 4-6 | 5-7 | 5-7 |

| 鎖模壓力(Ton) | 1.5 | 3.9 | 4.4 | 5.6 | 10 |

| 油箱容量(Gallon) | 38 | 55 | 60 | 80 | 120 |

| 加熱點數(ZONE) | 5 | 4 | 4 | 6 | 5 |

| 加熱容量(KW) | 8 | 9.5 | 12.5 | 16.8 | 18 |

| 總電力(KW) | 18 | 21 | 30 | 35 | 48 |

| 押出量(kg/hr) | 15 | 24 | 36 | 55 | 75 |

| 每小時空循環(time/hr) | 1285 | 1030 | 880 | 720 | 650 |

| 產品容量(c.c./L) | 15-500 | 60-1000 | 150-2500 | 500-5000 | 1L-10L |

| 產品重量(g.) | 5-40 | 10-100 | 20-170 | 40-280 | 80-500 |

| 產品最大最小直徑(m/m) | 10-75 | 20-100 | 30-140 | 50-200 | 80-260 |

| 模嘴外徑(m/m) | 50 | 56 | 80 | 150 | 200 |

| 模中心距離(m/m) | * | * | * | * | * |

| 開閉模極限(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 |

| 容模長度(m/m) | 100-300 | 126-232 | 156-292 | 200-400 | 236-452 |

| 容模寬度(m/m) | 300 | 300 | 350 | 420 | 480 |

| 機器淨重(kg) | 2300 | 2800 | 3300 | 4200 | 7100 |

| 機器尺寸(m) | 2.9*1.37*2.3 | 3*1.4*2.3 | 3*1.5*2.3 | 3.6*1.6*2.6 | 4.2*1.7*2.7 |

| 型號 | FS-40 HDSO | FS-45 HDSO | FS-55 HDSO | FS-65 HDSO | FS-75 HDSO |

| 使用塑料 | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 40 | 45 | 55 | 65 | 75 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 5 | 7.5 | 10 | 15 | 40 |

| 幫浦驅動馬力(HP) | 5 | 7.5 | 10 | 10 | 20 |

| 選配空壓機搭配馬力(HP) | 5 | 5 | 7.5 | 7.5 | 10 |

| 空氣壓力(kg/cm2) | 4-6 | 4-6 | 4-6 | 5-7 | 5-7 |

| 鎖模壓力(Ton) | 2.8 | 3.9 | 4.4 | 5.6 | 10 |

| 油箱容量(Gallon) | 38 | 55 | 60 | 80 | 120 |

| 加熱點數(ZONE) | 6 | 6 | 7 | 9 | 9 |

| 加熱容量(KW) | 7.5 | 10.25 | 13.6 | 17.5 | 25 |

| 總電力(KW) | 15.5 | 22 | 33 | 45 | 56 |

| 押出量(kg/hr) | 15 | 24 | 36 | 55 | 85 |

| 每小時空循環(time/hr) | 1285 | 1030 | 880 | 720 | 650 |

| 產品容量(c.c./L) | 15-200 | 40-500 | 100-1250 | 280-1800 | 0.5L-2.5L |

| 產品重量(g.) | 4-25 | 5-40 | 10-100 | 20-170 | 40-170 |

| 產品最大最小直徑(m/m) | 10-65 | 20-70 | 30-85 | 40-100 | 40-130 |

| 模嘴外徑(m/m) | 38 | 42 | 50 | 65 | 80 |

| 模中心距離(m/m) | 85 | 100 | 120 | 160 | 250 |

| 開閉模極限(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 |

| 容模長度(m/m) | 100-210 | 126-232 | 156-292 | 200-400 | 236-452 |

| 容模寬度(m/m) | 230 | 300 | 350 | 420 | 480 |

| 機器淨重(kg) | 2400 | 3000 | 3400 | 4400 | 7300 |

| 機器尺寸(m) | 2.3*1.4*2.2 | 3*1.4*2.3 | 3*1.5*2.3 | 3.8*2.1*2.6 | 4.3*3*2.9 |

| 型號 | FS-40 HTSO | FS-45 HTSO | FS-55 HTSO | FS-65 HTSO | FS-75 HTSO |

| 使用塑料 | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 40 | 45 | 55 | 65 | 75 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 5 | 7.5 | 10 | 15 | 25 |

| 幫浦驅動馬力(HP) | 5 | 7.5 | 10 | 10 | 15 |

| 選配空壓機搭配馬力(HP) | 7.5 | 7.5 | 10 | 10 | 15 |

| 空氣壓力(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 | 5-7 |

| 鎖模壓力(Ton) | 2.8 | 3.9 | 4.4 | 6.9 | 10 |

| 油箱容量(Gallon) | 38 | 55 | 60 | 80 | 120 |

| 加熱點數(ZONE) | 8 | 8 | 9 | 10 | 10 |

| 加熱容量(KW) | 8.5 | 12 | 15 | 19.3 | 21.5 |

| 總電力(KW) | 16.5 | 23.5 | 32 | 47 | 52.5 |

| 押出量(kg/hr) | 15 | 24 | 36 | 55 | 75 |

| 每小時空循環(time/hr) | 1250 | 1000 | 850 | 720 | 650 |

| 產品容量(c.c./L) | 10-125 | 20-325 | 40-825 | 100-1000 | 180-1500 |

| 產品重量(g.) | 3-10 | 5-25 | 10-50 | 10-90 | 15-145 |

| 產品最大最小直徑(m/m) | 10-45 | 20-55 | 30-55 | 30-80 | 30-95 |

| 模嘴外徑(m/m) | 30 | 37 | 40 | 55 | 80 |

| 模中心距離(m/m) | 75+75 | 85+85 | 100+100 | 120+120 | 120+120 |

| 開閉模極限(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 |

| 容模長度(m/m) | 100-210 | 126-232 | 156-292 | 200-380 | 236-452 |

| 容模寬度(m/m) | 230 | 300 | 350 | 420 | 480 |

| 機器淨重(kg) | 2600 | 3200 | 3700 | 4700 | 7600 |

| 機器尺寸(m) | 2.3*1.4*2.2 | 3*1.4*2.3 | 3*1.5*2.3 | 3.8*2.1*2.6 | 4.2*1.7*2.7 |

| 型號 | FS-55 HFSO | FS-65 HFSO | FS-75 HFSO | FS-90 HFSO |

| 使用塑料 | PE/PP | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 55 | 65 | 75 | 90 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 15-60 | 15-60 | 15-58 | 15-58 |

| 變頻馬達(HP) | 15 | 20 | 30 | 50 |

| 幫浦驅動馬力(HP) | 10 | 10 | 15 | 15 |

| 選配空壓機搭配馬力(HP) | 15 | 15 | 20 | 20 |

| 空氣壓力(kg/cm2) | 6-8 | 6-8 | 6-8 | 6-8 |

| 鎖模壓力(Ton) | 4.4 | 5.6 | 10 | 13 |

| 油箱容量(Gallon) | 60 | 80 | 120 | 250 |

| 加熱點數(ZONE) | 11 | 17 | 13 | 15 |

| 加熱容量(KW) | 16.5 | 21.3 | 25.7 | 30 |

| 總電力(KW) | 37.5 | 47 | 61 | 80 |

| 押出量(kg/hr) | 36 | 55 | 75 | 10 |

| 每小時空循環(time/hr) | 750 | 750 | 650 | 650 |

| 產品容量(c.c./L) | 30-300 | 100-500 | 300-1000 | 500-2500 |

| 產品重量(g.) | 10-25 | 10-40 | 15-90 | 40-170 |

| 產品最大最小直徑(m/m) | 20-55 | 30-55 | 30-90 | 30-90 |

| 模嘴外徑(m/m) | 37 | 42 | 50 | 75 |

| 模中心距離(m/m) | 90+90 | 90+90 | 120+120 | 120+120 |

| 開閉模極限(m/m) | 140-410 | 150-540 | 160-670 | 160-670 |

| 容模長度(m/m) | 156-292 | 200-380 | 236-452 | 250-550 |

| 容模寬度(m/m) | 380 | 450 | 510 | 550 |

| 機器淨重(kg) | 4000 | 5000 | 7900 | 9500 |

| 機器尺寸(m) | 3.1*1.8*2.3 | 4.23*2.6*3 | 4.3*2*2.7 | 5.2*3.1*3.5 |

| 型號 | FS-45 HSDO | FS-55 HSDO | FS-65 HSDO | FS-75 HSDO |

| 使用塑料 | PE/PP | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 45 | 55 | 65 | 75 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 15-61 | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 7.5 | 10 | 15 | 30 |

| 幫浦驅動馬力(HP) | 7.5 | 10 | 10 | 15 |

| 選配空壓機搭配馬力(HP) | 10 | 15 | 15 | 20 |

| 空氣壓力(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 |

| 鎖模壓力(Ton) | 3.9 | 4.4 | 6.9 | 10 |

| 油箱容量(Gallon) | 60 | 80 | 120 | 160 |

| 加熱點數(ZONE) | 4 | 4 | 5 | 5 |

| 加熱容量(KW) | 9.5 | 12.5 | 16.8 | 18 |

| 總電力(KW) | 22 | 28 | 37 | 53 |

| 押出量(kg/hr) | 24 | 36 | 55 | 75 |

| 每小時空循環(time/hr) | 1030*2 | 880*2 | 720*2 | 650*2 |

| 產品容量(c.c./L) | 40-500 | 65-1250 | 150-2500 | 500-5000 |

| 產品重量(g.) | 5-40 | 10-100 | 20-170 | 40-280 |

| 產品最大最小直徑(m/m) | 10-75 | 20-100 | 30-140 | 50-200 |

| 模嘴外徑(m/m) | 56 | 80 | 150 | 200 |

| 模中心距離(m/m) | * | * | * | * |

| 開閉模極限(m/m) | 130-320 | 140-410 | 150-540 | 160-670 |

| 容模長度(m/m) | 126-232 | 156-292 | 200-380 | 236-452 |

| 容模寬度(m/m) | 250 | 300 | 330 | 360 |

| 機器淨重(kg) | 6400 | 6900 | 7400 | 8300 |

| 機器尺寸(m) | 3*1.8*2.5 | 3*1.9*2.5 | 3.2*2*2.8 | 4.2*2.1*2.9 |

| 型號 | FS-45 HDDO | FS-55 HDDO | FS-65 HDDO | FS-75 HDDO |

| 使用塑料 | PE/PP | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 45 | 55 | 65 | 75 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 15-61 | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 10 | 10 | 15 | 30 |

| 幫浦驅動馬力(HP) | 7.5 | 10 | 10 | 15 |

| 選配空壓機搭配馬力(HP) | 10 | 15 | 15 | 20 |

| 空氣壓力(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 |

| 鎖模壓力(Ton) | 3.9 | 4.4 | 6.9 | 10 |

| 油箱容量(Gallon) | 60 | 80 | 120 | 160 |

| 加熱點數(ZONE) | 6 | 7 | 8 | 8 |

| 加熱容量(KW) | 10.25 | 13.6 | 17.5 | 19 |

| 總電力(KW) | 26 | 30 | 38 | 54 |

| 押出量(kg/hr) | 32 | 36 | 55 | 75 |

| 每小時空循環(time/hr) | 1030*2 | 880*2 | 720*2 | 650*2 |

| 產品容量(c.c./L) | 30-200 | 40-500 | 100-1000 | 280-2000 |

| 產品重量(g.) | 4-20 | 5-40 | 10-65 | 20-110 |

| 產品最大最小直徑(m/m) | 10-65 | 20-70 | 30-85 | 40-110 |

| 模嘴外徑(m/m) | 42 | 50 | 65 | 80 |

| 模中心距離(m/m) | 100 | 120 | 140 | 160 |

| 開閉模極限(m/m) | 130-320 | 140-410 | 150-540 | 160-670 |

| 容模長度(m/m) | 126-232 | 156-292 | 200-380 | 236-452 |

| 容模寬度(m/m) | 250 | 300 | 330 | 360 |

| 機器淨重(kg) | 6500 | 7000 | 7500 | 8500 |

| 機器尺寸(m) | 3*1.8*2.5 | 3.2*2*2.8 | 3.4*3*3 | 4.2*3.1*3.1 |

| 型號 | FS-55 HTDO | FS-65 HTDO | FS-75 HTDO |

| 使用塑料 | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 55 | 65 | 75 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 10 | 15 | 30 |

| 幫浦驅動馬力(HP) | 10 | 10 | 15 |

| 選配空壓機搭配馬力(HP) | 15 | 15 | 20 |

| 空氣壓力(kg/cm2) | 4-6 | 5-7 | 5-7 |

| 鎖模壓力(Ton) | 4.4 | 6.9 | 10 |

| 油箱容量(Gallon) | 110 | 120 | 160 |

| 加熱點數(ZONE) | 9 | 10 | 10 |

| 加熱容量(KW) | 15 | 19.3 | 21.5 |

| 總電力(KW) | 32 | 40 | 56.5 |

| 押出量(kg/hr) | 36 | 55 | 75 |

| 每小時空循環(time/hr) | 850*2 | 720*2 | 650*2 |

| 產品容量(c.c./L) | 15-300 | 50-600 | 100-1000 |

| 產品重量(g.) | 5-25 | 8-45 | 10-70 |

| 產品最大最小直徑(m/m) | 10-55 | 20-70 | 30-90 |

| 模嘴外徑(m/m) | 40 | 55 | 80 |

| 模中心距離(m/m) | 85+85 | 100+100 | 120+120 |

| 開閉模極限(m/m) | 140-410 | 150-540 | 160-670 |

| 容模長度(m/m) | 156-292 | 200-380 | 236-452 |

| 容模寬度(m/m) | 300 | 330 | 360 |

| 機器淨重(kg) | 7100 | 7600 | 8700 |

| 機器尺寸(m) | 3.4*2*2.8 | 3.6*3*3 | 4.4*3.1*3.1 |

| 型號 | FS-55 HFDO | FS-65 HFDO | FS-75 HFDO |

| 使用塑料 | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 55 | 65 | 75 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 15 | 20 | 30 |

| 幫浦驅動馬力(HP) | 10 | 10 | 15 |

| 選配空壓機搭配馬力(HP) | 15 | 15 | 20 |

| 空氣壓力(kg/cm2) | 6-8 | 6-8 | 6-8 |

| 鎖模壓力(Ton) | 4.4 | 6.9 | 10 |

| 油箱容量(Gallon) | 80 | 120 | 160 |

| 加熱點數(ZONE) | 11 | 13 | 13 |

| 加熱容量(KW) | 16.5 | 20.8 | 25.7 |

| 總電力(KW) | 37.5 | 48 | 61 |

| 押出量(kg/hr) | 36 | 55 | 75 |

| 每小時空循環(time/hr) | 750*2 | 750*2 | 650*2 |

| 產品容量(c.c./L) | 50-250 | 100-400 | 200-600 |

| 產品重量(g.) | 5-20 | 10-30 | 20-50 |

| 產品最大最小直徑(m/m) | 20-55 | 20-55 | 20-70 |

| 模嘴外徑(m/m) | 37 | 42 | 50 |

| 模中心距離(m/m) | 85+85+85 | 85+85+85 | 100+100+100 |

| 開閉模極限(m/m) | 140-410 | 150-540 | 160-670 |

| 容模長度(m/m) | 156-292 | 200-380 | 236-452 |

| 容模寬度(m/m) | 300 | 330 | 360 |

| 機器淨重(kg) | 7200 | 7700 | 8900 |

| 機器尺寸(m) | 3.4*2.2*3.1 | 3.6*2.3*3.2 | 4.4*3.3*3.3 |

| 型號 | FS-40 HSSD | FS-45 HSSD | FS-55 HSSD | FS-65 HSSD | FS-75 HSSD |

| 使用塑料 | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 40/25 | 45/25 | 55/25 | 65/25 | 75/25 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 5/2 | 7.5/2 | 10/2 | 15/2 | 25/2 |

| 幫浦驅動馬力(HP) | 5 | 7.5 | 10 | 10 | 15 |

| 選配空壓機搭配馬力(HP) | 5 | 5 | 7.5 | 7.5 | 10 |

| 空氣壓力(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 | 5-7 |

| 鎖模壓力(Ton) | 2.8 | 3.9 | 4.4 | 6.9 | 10 |

| 油箱容量(Gallon) | 38 | 55 | 60 | 80 | 120 |

| 加熱點數(ZONE) | 6 | 6 | 6 | 7 | 7 |

| 加熱容量(KW) | 9.5 | 12 | 15 | 19.5 | 22 |

| 總電力(KW) | 19 | 25 | 32 | 40.5 | 44 |

| 押出量(kg/hr) | 15 | 24 | 42 | 55 | 75 |

| 每小時空循環(time/hr) | 1285 | 1030 | 880 | 720 | 650 |

| 產品容量(c.c./L) | 15-500 | 60-1000 | 150-2500 | 1L-5L | 1L-10L |

| 產品重量(g.) | 5-40 | 10-100 | 20-170 | 40-280 | 80-500 |

| 產品最大最小直徑(m/m) | 10-75 | 20-100 | 30-140 | 50-200 | 80-260 |

| 模嘴外徑(m/m) | 50 | 56 | 80 | 150 | 200 |

| 模中心距離(m/m) | * | * | * | * | * |

| 開閉模極限(m/m) | 120-230 | 130-410 | 140-540 | 150-540 | 160-670 |

| 容模長度(m/m) | 126-232 | 156-292 | 200-380 | 236-452 | 236-452 |

| 容模寬度(m/m) | 230 | 300 | 350 | 420 | 480 |

| 機器淨重(kg) | 2600 | 3100 | 3600 | 4500 | 7400 |

| 機器尺寸(m) | 2.6*1.8*2.7 | 3*1.9*2.8 | 3.3*2*2.9 | 3.6*1.6*3 | 3.9*2.2*3.1 |

| 型號 | FS-55 HSSC | FS-65 HSSC | FS-75 HSSC |

| 使用塑料 | PE/PP | PE/PP | PE/PP |

| 螺桿直徑(m/m) | 55/55 | 65/65 | 7575 |

| 螺桿比例(L/D) | 24/1 | 24/1 | 24/1 |

| 螺桿轉速(r.p.m.) | 15-60 | 15-60 | 15-58 |

| 變頻馬達(HP) | 10/10 | 15/15 | 25/25 |

| 幫浦驅動馬力(HP) | 10 | 10 | 15 |

| 選配空壓機搭配馬力(HP) | 15 | 15 | 20 |

| 空氣壓力(kg/cm2) | 6-8 | 6-8 | 6-8 |

| 鎖模壓力(Ton) | 4.4 | 6.9 | 10 |

| 油箱容量(Gallon) | 60 | 80 | 120 |

| 加熱點數(ZONE) | 6 | 6 | 7 |

| 加熱容量(KW) | 19 | 24.5 | 26 |

| 總電力(KW) | 43 | 56 | 77 |

| 押出量(kg/hr) | 42 | 55 | 75 |

| 每小時空循環(time/hr) | 880 | 720 | 600 |

| 產品容量(c.c./L) | 150-2500 | 1L-5L | 1L-10L |

| 產品重量(g.) | 20-170 | 40-280 | 80-500 |

| 產品最大最小直徑(m/m) | 30-140 | 50-200 | 80-260 |

| 模嘴外徑(m/m) | 80 | 150 | 200 |

| 模中心距離(m/m) | * | * | * |

| 開閉模極限(m/m) | 140-540 | 150-540 | 160-670 |

| 容模長度(m/m) | 200-380 | 236-452 | 236-452 |

| 容模寬度(m/m) | 350 | 420 | 480 |

| 機器淨重(kg) | 3600 | 4500 | 7400 |

| 機器尺寸(m) | 3.3*2*2.9 | 3.6*2.1*3 | 3.9*2.2*3.1 |

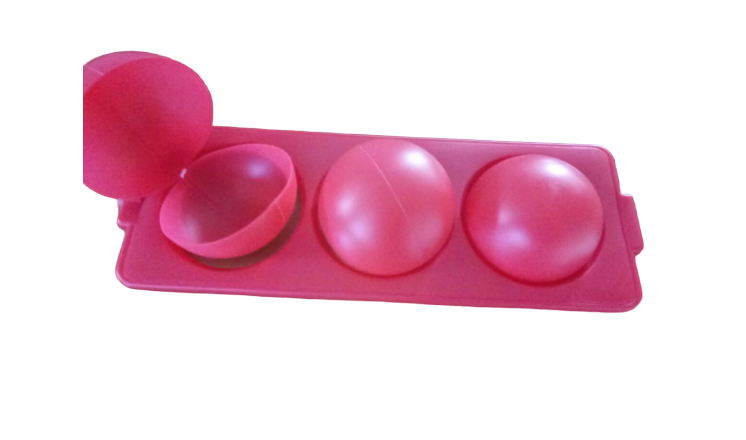

Sample Bottles

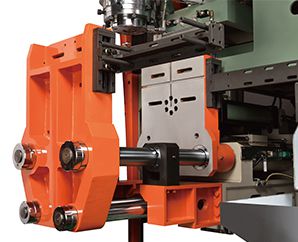

Silde Bars for Clamping & Linear Slideway for Carriages

Four Column Slide Bars for Mold Clamping

Direct-mounted Motor, Made in Germany

應用產業

洗手瓶 / 清潔用品

水瓶或是特定容器

機油瓶/機油桶

氧氣面罩/真空傷口引流罐

居家/家用品/美容用品

居家/家用品/清潔用品

居家/家用品/美容用品

居家/家用品/美容用品

真空傷口引流罐

Toys

汽車配件

居家/家用品/美容用品

戶外用品

居家/家用品/清潔用品

睫毛膏瓶子

農藥瓶子