全自動押出中空吹氣成型機 L系列

- 特性

- 機械型號索引系列

- L 系列(前向取出機型)

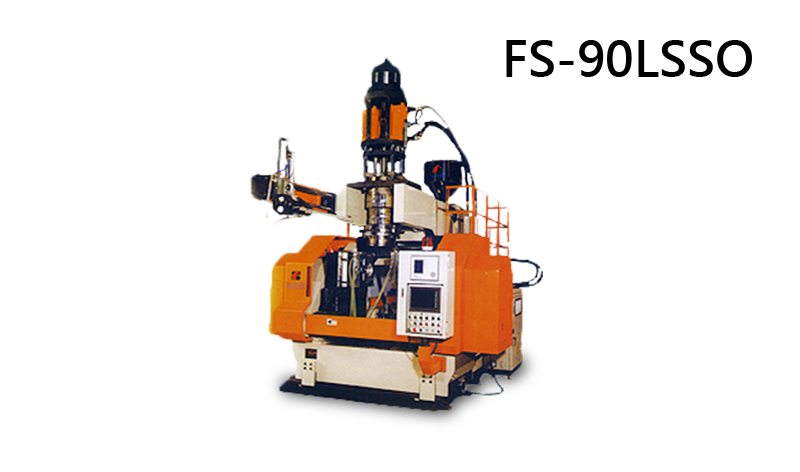

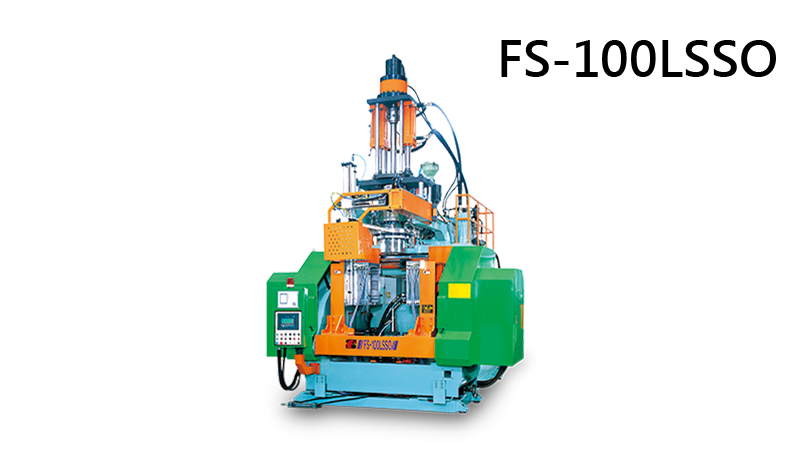

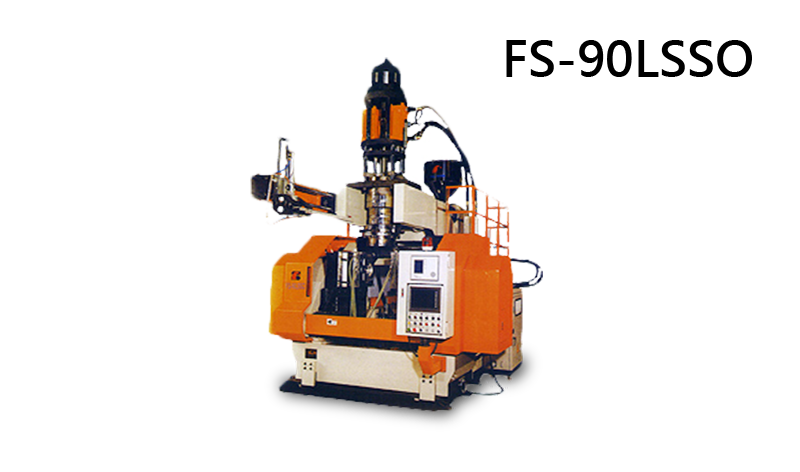

- 照片

- 特性

- 操控面板結合觸控式螢幕功能及分離式電控箱,便利操作。

- 此機型可加裝多點式厚薄控制器。

- 螺桿及輸料管以特殊鋼材加工並且經氮化處理。

- 入料口採冷卻水裝置,控制溫度。

- 吹氣針部份具有水冷卻裝置。

- 創新機械手臂設計,可自動取出成品。

- 完善的安全防護裝置,提供作業員安全、舒適的工作環境。

- 高效能油壓迴路系統,雙向油壓缸加強鎖模力。

| 機械型號索引系列 |

| 螺桿直徑(M/M) | 機械類別 | 模頭 | 模架 | 產品型式 | |

|---|---|---|---|---|---|

| FS- | 40 | (H) 平移式開關模採用線性滑桿 | (S) 單模頭 | (S) 單模架 | (O) 一般 |

| 45 | (P) 平行式移模 | (D) 雙模頭 | (D) 雙模架 | (C) 雙色 | |

| 55 | (O) 標準型 / 斜移式 | (T) 三模頭 | (D) 雙層 | ||

| 65 | (A) 空壓式 | (F) 四模頭 | (T) 三層 | ||

| 75 | (L) 前向取出機型 | (E) 八模頭 | (F) 四層 | ||

| 80 | (I) 側向取出機型 | (L) 六層 | |||

| 90 | (V) 視窗 | ||||

| 100 | (P) PC奶瓶 | ||||

| 範例 | |||||

| FS- | 65 | P | D | S | D |

| 型號 | FS-75LSSO | FS-80LSSO | FS-90LSSO | FS-100LSSO | FS-120LSSO | ||

|---|---|---|---|---|---|---|---|

| 使用塑料 | PE | PE | PE | PE | PE | ||

| 1 | 產品容量 | Liter | 1-10 | 10-30 | 30-50 | 50-100 | 100-250 |

| 2 | 產品直徑 | m/m | 80-260 | 120-350 | 150-400 | 180-580 | 260-650 |

| 3 | 螺桿直徑 | m/m | 75 | 80 | 90 | 100 | 120 |

| 4 | 螺桿比例 | L/D | 24/1 | 24/1 | 24/1 | 28/1 | 28/1 |

| 5 | 押出量 | Kg/hr | 100 | 120 | 140 | 210 | 270 |

| 6 | 儲料量 | Kg | 2.5 | 2.5 | 5 | 7-12 | 26 |

| 7 | 螺桿驅動 變頻馬達 | HP | 30 | 40 | 50 | 60 | 100 |

| 8 | 螺桿驅動 油壓馬達 | C.C. | 1450 | 2000 | 2500 | 3000 | 4500 |

| 9 | 螺桿轉速 | r.p.m | 15-65 | 20-65 | 20-65 | 20-65 | 20-65 |

| 10 | 油壓驅動 變頻馬達 | HP | 25 | 30 | 30 | 40 | 75 |

| 11 | 油壓驅動 油壓馬達 | HP | 20 | 50 | 75 | 100 | 125 |

| 12 | 厚薄控制動力 | HP | 5 | 5 | 7.5 | 10 | 10 |

| 13 | 空氣壓縮機(選購用) | HP | 7.5 | 15 | 15 | 20 | 30 |

| 14 | 空氣壓力 | kg/cm2 | 5-7 | 5-7 | 6-8 | 6-8 | 6-8 |

| 15 | 鎖模壓力 | ton | 28 | 42 | 50 | 100 | 162 |

| 16 | 油箱容量 | Gallon | 80 | 100 | 140 | 200 | 210 |

| 17 | 加熱點數 | Zone | 6 | 7 | 7 | 10 | 10 |

| 18 | 加熱電量 | Kw | 26 | 28 | 32 | 36 | 45 |

| 19 | 總電力 | Kw | 68 | 81 | 92 | 111 | 176 |

| 20 | 模嘴外徑 | m/m | 200 | 280 | 350 | 450 | 650 |

| 21 | 開閉模極限 | m/m | 200-700 | 230-930 | 340-1000 | 360-1200 | 500-2300 |

| 22 | 容模長度 | m/m | 680 | 775 | 850 | 1200 | 1500 |

| 23 | 容模寬度 | m/m | 500 | 640 | 820 | 1000 | 1300 |

| 24 | 機械水消耗量 | L/hr | 900 | 900 | 1000 | 1200 | 1500 |

| 25 | 模具水消耗量 | L/min | 230 | 230 | 230 | 230 | 450 |

| kcal/hr | 31500 | 31500 | 46623 | 46623 | 246500 | ||

| 26 | 機器淨重 | ton | 7.2 | 11 | 12 | 18 | 32 |

| 27 | 機器尺寸<L*W*H> | m | 3.4*2.5*2.8 | 3.8*2.8*2.8 | 5*3*3.3 | 5.5*3.5*3.3 | 5.7*9.6*6 |

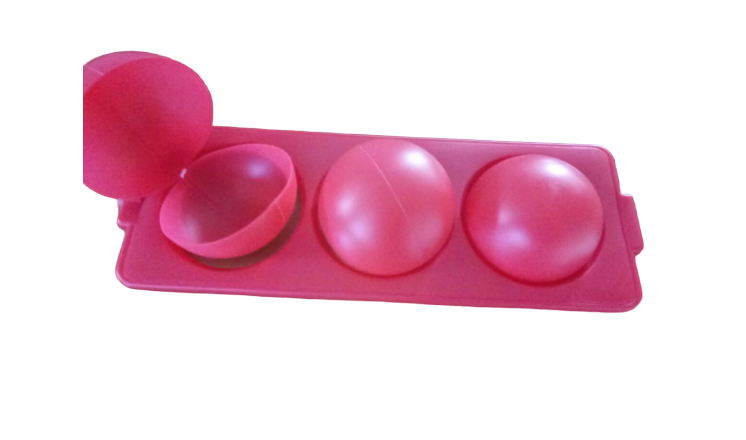

Sample bottles

Sample bottles

Sample bottles

Sample bottles

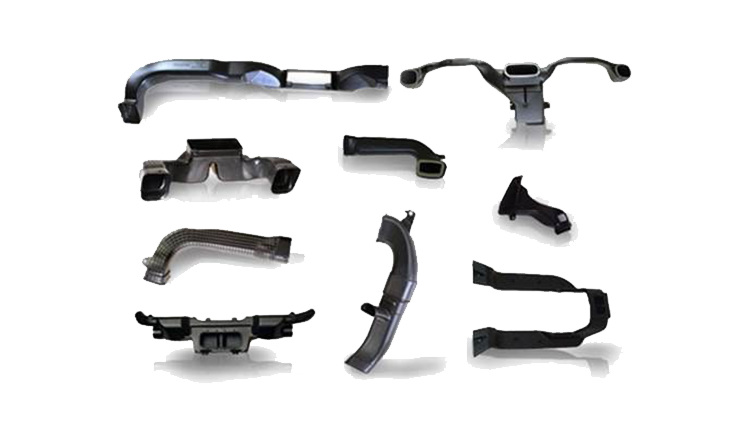

應用產業

澆水桶

汽車配件

210L/250L – 化工用雙環桶

園藝用品

冰桶

椅墊

戶外用品

水塔